Alternative Feed Ingredients

By J.L. Pierce K.A. Jacques A.J. Pescatore and A.E. Sefton Alltech-University of Kentucky Nutrition

Features New Technology ProductionStrategies on how to get the most from them

After a year of record feed and grain prices, it is apparent that North

American livestock and poultry producers have embraced alternative feed

ingredients and new technologies at the most rapid pace in the history

of the industry.

After a year of record feed and grain prices, it is apparent that North American livestock and poultry producers have embraced alternative feed ingredients and new technologies at the most rapid pace in the history of the industry. Most producers have a new outlook on evaluating profitability, or in worst cases, loss management. Now more than ever, it is necessary to take a holistic approach to animal production rather than viewing feed cost as an isolated economic driver.

|

|

| Managing Feed Cost Alltech’s James Pierce and colleagues write that managing feed cost utilizing alternative ingredients involves more than just least cost feed formulation. Advertisement

|

Admittedly, feed represents the largest single cost in poultry production. However, managing feed is the key to a successful operation. Feed management is multi-factored and includes house management, bird management, feed management, ingredient management, feed formulation, and feed additives including enzymes. These factors are not independent but rather are interrelated and must be co-ordinated if feed cost is to be optimized. Feed intake is dependent on house temperature, diet density, feeding schedule, and bird age. Least cost formulation can be part of the picture, but it cannot be the sole technology if returns are to be maximized.

Birds will lower feed intake by one per cent for each one degree (farhenheit) increase in temperature. A barn containing 100,000 birds consuming 20 lbs per 100 birds uses 10 tons of feed per day, or 70 tons per week. If barn temperature is increased by just two degrees F, there will be a savings of 1.4 tons of feed per week. To achieve this savings may or may not require the use of a more dense feed. The cost of a more dense feed must be balanced by reducing feed quantity. In meat birds, temperature may be lowered to stimulate greater intake and thus greater weight gain. Birds do not perfectly regulate intake to match nutrient requirements. In fact, genetic selection in meat birds has partially eliminated this self-regulatory mechanism.

Bird Management

The introduction of the United Egg Producers (UEP) space requirements has in many cases increased the productivity of layers. Productivity peaks above 95 per cent are becoming common and weeks above 90 per cent are becoming the norm. Managing these high producing flocks necessitates changes in many management strategies. In addition the lower population densities have made it more difficult to maintain winter barn temperatures.

|

|

Feed Management

Feed intake is a key to managing feed cost. Feed intake is dependent on several management factors, including house temperature, feeder management, feed freshness, feed consistency, and economic optimum nutrient profiles:

House temperature: Since production is peaking while layers are increasing in body weight, there may be need to encourage feed intake by keeping temperature low. With flocks coming into lay during the summer, this temperature control alone may not be sufficient to optimize feed intake. More dense feeds may be needed to meet the nutrient requirements or a midnight feeding may need to be introduced.

(Remember to eliminate midnight feedings when the flock peaks and body weights begin to meet target.)

Feed management: Feed intake is encouraged by running the feeders more often. The sound of running feeders triggers feed intake, similar to hearing a refrigerator door open. Conversely, eliminating a feeding will lower feed intake. This must be done with care since you do not want to discourage feed intake too much and negatively impact production. One must be aware of feeder space when reducing feed times, all birds have a desire to eat when the feedings are returned. It can often be successfully accomplished by moving afternoon feedings closer together until they overlap and thus reduce total number of feedings by one.

Remember, that much of egg material is laid down in the morning, so it is important to have feed available when the birds wake up and during the morning while most of the egg is being formed. In the afternoon much of the egg has been formed, so the nutrient demand is not as high. This is the best time of day for feeders to be empty. Birds need to go to bed with full stomachs, so make sure that feed is available in the later afternoon and evening.

Feed freshness: Especially in summer, feed vitamins and enzymes can deteriorate in the heat if stored too long. Fat can go rancid. These will all have a negative effect on feed intake and, more importantly, on nutrient intake. Thus, feed should be delivered frequently, and maybe more importantly, the inventory in the bin should be managed in such a way that first feed in is first feed out. Unless there is provision made, feed tanks may empty down the middle so that there is a “doughnut” of old feed at the edge of the bottom of the tank. This “doughnut” will be the last feed to exit the feeder when the tank is emptied.

Feed consistency: With mash feed, the grind of the feed and feeder management are important for optimum production:

Ingredients can separate such that dense particles such as limestone will tend to be in either the first or last cages. The first indication of this separation is often poor eggshell quality or broken eggs. Separation can often be prevented by changing the grind of the feed or via feed delivery management.

Recently, by accident, a producer who was mixing his own feed found that by grinding the feed less fine, shell quality improved. He now grinds the corn so that some whole kernels are in the feed or else he will add unground wheat. The birds are now more productive and less time and energy are required to grind and mix feed. Thus, returns are improved. Broiler producers have for many years known that whole wheat or coarse ground corn will cause the gizzard to work more and lead to better flock health. The only downside is larger gizzards.

Economic optimum nutrient profiles: Primary breeders give recommended nutrient profiles for their birds to achieve “optimum biological” performance. Performance increases as you approach these guidelines. However, exceeding these guidelines will not necessarily give better performance. Breast meat yield may be the exception. The producer needs to determine the “economic optimum” for their circumstances.

Alternative Ingredients

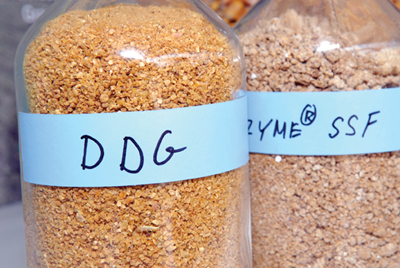

Alternative feed ingredients must be part of the producer’s program. Alternative ingredients are all ingredients that are available but not a part of your current program. Currently, distiller’s dried grains with solubles (DDGS), along with any variation of feedstock for the ethanol business or byproducts of biodiesel production, are considered to be alternative ingredients. Wheat milling and human food co-products, as well as new field crops, also fit this description.

Understanding the alternative ingredient, its nutrient profile, digestibility, consistency, and negative factors, is essential to optimizing its potential use. Enzyme use, just as with conventional ingredients, can enhance these ingredients and in some cases specific enzymes can increase their maximum rate of use. For example, Pierce and Stevenson (2008) demonstrated that the digestibility of DDGS can be increased when Allzyme® SSF (Alltech Inc.) is included in the diet.

Ingredient Management

Typically feed mills do not have enough bins. Therefore, there are usually limitations on available ingredients and compromises are necessary. Local conditions are always part of this formula. Opportunity ingredients should always be taken advantage of, but their effect on bird performance must be considered. Here variability of the ingredient must be understood. Enzymes, if properly selected, can minimize the effect of ingredient variability. Distiller’s dried grains with solubles a year ago was the hot topic. Variation in limestone quality is always crucial; limestone varies in solubility. Use of low soluble limestone is possible, but if high soluble limestone is followed by low soluble limestone, the result can be disastrous. With all ingredients, the key is to be knowledgeable and aware of changes.

Feed Formulation

Many feed programs are designed with a range of feeds available from which to choose. These are based on stage of production and level of feed intake. Choices for a flock approaching peak production may include: 18, 19, 20 or 21 lbs per 100 lbs feed intake. If you compare these alternatives, they provide the bird similar allowances of key nutrients at each level of intake.

Leeson and Summers (2005) give the daily protein need for a Leghorn as 20 g. Thus, the protein allowance would be 24 per cent for a flock consuming 18 lbs of feed per 100 lbs; 23 per cent protein for a flock consuming 19 lbs of feed per 100 lbs; 22 per cent for a flock consuming 20 lbs of feed per 100 lbs. Thus, at any given level of feed intake, birds are fed a comparable protein allowance; similar calculations could be made for other nutrients. As feed intake increases, ration density decreases so that bird nutritional requirements are met at all intake levels. (Feed intake increases as house temperature decreases, and decreases as temperature increases, as previously discussed.)

Feed Additives, including Feed Enzymes

Feed enzymes, such as Allzyme VEGPRO™ (Alltech Inc.) and or Allzyme® SSF, may be useful since they lower metabolic heat increment, meeting bird nutritional requirements with less dense diet. Thus, in hot weather nutrient intake can be encouraged with lower heat increments, while increasing digestible nutrient intake at a constant total feed intake.

Later, with layers, it may be advantageous to encourage the birds to lower feed intake by raising barn temperature. Another possibility in this situation is to add an enzyme such as Allzyme® SSF. When feed intake is high, lower density feeds are required so as not to oversupply birds with nutrients, excess energy, or key amino acids that may increase egg size above the target weight. In certain markets a 49-lb. average case weight is thought to be ideal. When the feed mill has limited numbers of bins, it may not be possible to produce low-density rations using such enzymes. Enzymes can reduce the cost of the feed, but would mean higher than desired nutrient density. Therefore, it may be desirable to increase barn temperature to reduce feed intake, and thus use a lower cost feed that includes an enzyme.

Season will influence whether this strategy applies. In the summer feed intake will be lower than in the winter. Thus, in the winter it is more likely that it would be desirable to raise barn temperature. The most economic way to increase barn temperature is to decrease the ventilation rate. However, this reduction may lead to increased ammonia levels, a less than desirable outcome. Crober (1995) reported that levels of ammonia could be reduced by half by adding De-Odorase® (Alltech Inc.) to the diet. This outcome resulted when the use of De-Odorase® commenced with a clean barn. In the case that Crober reported, egg numbers increased, while feed intake decreased; thus return improved. The effect on feed intake was at least in part because of the higher barn temperature and the lower barn ammonia. The influence of barn ammonia is, in part, due to better bird health, but it also means a better working environment for the barn manager. When barn managers are more comfortable in the barn they will more likely spend more time assuring the birds are better managed. This work was done with layers but the principles apply equally to meat birds.

Improved genetics, equipment, bird management, and nutrition means that layer flocks are peaking and sustaining higher production compared with only a few years ago. Weeks over 95 per cent production is a talking point now. This means that peak feed is fed for longer periods. It was a common practice to step down protein and amino acids along with available phosphorus after peak. It is hard to reduce amino acids in flocks at production over 95 per cent. Such reduction may be necessary but must be done with care to control egg size. However, available phosphorus still needs to be reduced or shell quality may suffer.

Phosphorus is also important in meat birds. Their requirement decreases as birds age. Higher than necessary available phosphorus can negatively impact feed efficiency.

Summary

Thus, managing feed cost involves more than just least cost feed formulation. It involves managing feed intake and diet density so as to minimize cost per egg or pound of meat. Bird management, house management, ingredient management, feed management, feed formulation, and the selected use of feed additives, including enzymes, can all contribute to maximizing profit. Getting the most energy from ingredients is a component of the overall strategy. In short, to optimize return, the producer must manage the flock and not depend on the nutritionist alone.

This research was presented at the 2009 Midwest Poultry Federation Convention in Saint Paul, Minn.

References

Crober D. 1995. Reducing ammonia and flies in layer operations with yucca. In: Biotechnology in the Feed Industry, Proceedings of Alltech’s 11th Annual Symposium, Lexington, Ky. (Lyons TP, Jacques KA, eds.): Nottingham University Press, Nottingham, U.K.: 415-420.

Leeson S, and J D Summers. 2005. Commercial Poultry Nutrition. 3rd ed. Univ. Books, Guelph, Ontario, Canada.

Pierce J, and Z Stevenson, 2008. Nutrition and gut microbiology: redirecting nutrients from the microbes to the host animal with Allzyme® SSF. In: Gut Efficiency; the key ingredient in pig and poultry production (Eds. JA Taylor Pickard and P Spring) Wageningen Academic Publishers, The Netherlands.

Print this page