Dihydrogen Monoxide: It’s just water!

By Mary K. Foy

Features Barn ManagementA few basic steps can go a long way towards improving water quality.

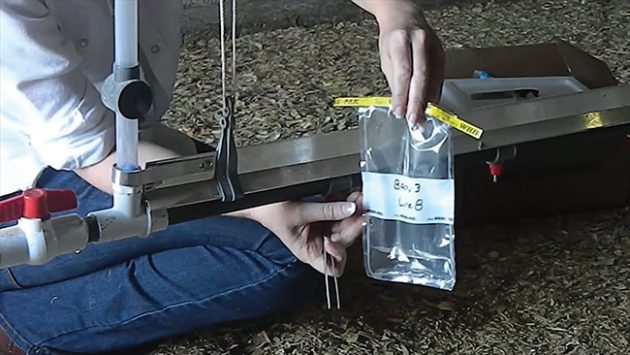

Pictured is what comes out when waterlines are cleaned properly.

PHOTO CREDIT: Proxy-Clean Products.

Pictured is what comes out when waterlines are cleaned properly.

PHOTO CREDIT: Proxy-Clean Products. How many times have you decided to start a water program and begun the process of gathering information only to give up shortly thereafter because of the overload of complicated and, often, conflicting information? Why is it our industry sometimes finds the need to complicate things to such a degree that we outsmart ourselves right out of getting basic information to the producer?

I can’t build a car from scratch, but with a little guidance I can change a flat tire, replace a battery or even change the oil. I don’t have to know how to build a combustion engine to take care of some simple fixes that keep the car running. The same can be said for many of the systems we find on our farms – including the water system.

There are volumes of books written about water and its properties. In fact, I have a Handbook of Chlorination that takes two hands to carry! The point is, yes, water can be complicated, but sometimes we get stuck in that and miss the opportunity to do some basic work that may be the key to helping our water system and the treatment program we have chosen work.

When you ask for help with water, often the first thing a chemical company will tell you is to get a bacteria test. Here is where the battle is lost.

Right off the bat, the chemical company has given you what feels like an insurmountable task. How are you supposed to get the water tested? For what? Where will you get a sterile container for a bacteria test? What lab do you send it to? How do you even get the supplies needed to do sterile sampling? Are you supposed to drive that very day to get it shipped since it has to be at the lab within 48 hours – and all while being kept cold? Who has an icepack ready to go?

When the first step is an overwhelming one you often don’t get to the second or third one. Even with the best intentions, this first step can make you feel defeated.

What should really be the first step? If you haven’t cleaned between flocks and you don’t have a regular water treatment program, you have bacteria. You don’t have to test for them. First, clean your water lines when the barn is empty. Second, use a product that is labeled for use while birds are in the barn.

So, when do you do a bacteria test? If you have cleaned your water lines and have a water treatment program but want to test the efficacy of that program or if you have bird health issues then testing for bacteria is an option.

Let me add here that I am a microbiologist. I love bacteria testing, but what I love more is helping a grower get real results and after 15 years of working in water quality at both a research level, processing level and a products level I’ve seen multitudes of growers give up before they even got started because someone told them they have to get a bacteria test first.

Mineral test

A mineral test, however, can help right off the bat. Just about anyone has the supplies to do this test right now and it does not take any sterile containers or sampling. Knowing the mineral levels can often help you choose which water treatment program to go with or the filtration needed. Even those that do get mineral tests don’t always follow through, though.

What everyone keeps doing:

- Taking a mineral sample and getting it analyzed.

- Getting the results and not having a clue what they mean.

- Sticking it in a filing cabinet.

Try this instead:

- Search for previous mineral tests that have been performed

- If they are more than 5 years old get new tests done

- Consult the standard acceptable levels for agricultural water (Several Universities have this on their agricultural website)

- Develop a water plan

One program does not fit all

Another mistake we make is assuming the same program will work on another farm.

What everyone keeps doing:

- Farm #1 finished with the best flock ever so we decide to do the same thing with farm #2.

- Farm #2 gets set up with the same treatment system.

- Farm #2 does not improve.

- Farm #2 switches to another product, then six months later switches again, then six months later switches again and so on.

Try this instead:

- Get a mineral test done on farm #2 before suggesting any system at all.

- Go over the instructions on the label of the products being used while the person that will be actually using the chemicals is standing there.

- Remember, different chemicals have different instructions.

- Be prepared to test for the chemical at the end of the water line.

We tend to jump to the conclusion that a product is not working before we take a look at how we are using the product versus how it is supposed to be used according to the label.

Liquid chlorine + acid, gas chlorination, chlorine dioxide and hydrogen peroxide all have different steps that make them more effective. Call a company representative if you need to. A lot of times all the pieces are there, they just aren’t being used as intended.

How is the product being measured? Are you measuring chlorine? Be able to measure for free chlorine – that’s the chlorine that is available for oxidation (total chlorine measures free plus chlorine that is already bound – this is unhelpful). If you use a pool test kit, be sure you get one that measures free chlorine. These will be a little more expensive at around $100.

Are you measuring hydrogen peroxide? Use unexpired test strips or a titration type hydrogen peroxide test kit.

Right there on the farm you can get a rough estimate of how clean the water lines are. For your oxidizer, test not only what is going into the water line but also what is making it to the end. The cleaner the water line, the smaller the difference will be between those two numbers.

An expert demonstrates how to take a bacteria sample.

Acids

Finally, we can address the use of acids.

What everyone keeps doing:

- Adding the least expensive acid.

- Adding the acid they found in the anteroom.

- Adding an acid their neighbor uses.

Try this instead:

- Ask why the acid is being added:

- Is it for lowering pH for water uptake? If so, add inorganic acid.

- Is it for tightening intestinal health for a specific issue? If so, add organic acid.

Words of caution for acids

When used in conjunction with chlorine, inorganic acids can remove the protective chromium oxide layer and “pit” your stainless steel. In conjunction with chlorine, it can also damage the rubber components in the water system (i.e., seals, diaphragms).

If you plan to use an acid long term, look for an acid that is chloride free. These are more equipment friendly. To know if you are using an acid that is chloride free, check the SDS. Look for ingredients that contain chlorides, such as hydrogen chloride.

In terms of organic acids, they require more product to lower the pH in the water system. They also allow for fungal, mold and algae blooms.

Other things to keep in mind

Some minerals are clear so you don’t know they are there until you test (even iron, when it is in the ferrous form, is clear when dissolved).

Specific minerals need professional, specialized filtration systems.

The alkalinity of water can change the whole ball game when it comes to lowering pH – it’s why farm #1 may take half the amount of acid that farm #2 takes even though they have the same starting pH.

Some water treatment chemicals do not play well with others – ask the distributor, representative or manufacturer.

Just as we are able to do small things to keep our cars running, we can do small things to make sure our water treatment is effective. Call in the experts when the car won’t start but first make sure you don’t just need a new battery.

Mary K. Foy is the director of technical services for Proxy-Clean Products. The U.S. company’s cleaning solution is used in Canada as part of the Water Smart Program developed by Weeden Environments and Jefo Inc.

Print this page