Distiller’s Grains: An Opportunity?

By Matt Oryschak Eduardo Beltranena

Features Profiles ResearchersTaking a closer look at a 21st-century feedstuff

In 2008, we saw historic prices for wheat and similar highs for corn

and other coarse grains. American soybean meal also hovered around $450

US per tonne. While the world was preoccupied with the price of

spaghetti, livestock and poultry producers were faced with how to

scratch out a living from an ever-shrinking (and often negative) margin.

|

|

| Future feed? The recent surge in ethanol production means that byproducts such as dried distiller’s grains (inset) are becoming plentiful – but making them more useful as a poultry feed is challenging researchers.

|

In 2008, we saw historic prices for wheat and similar highs for corn and other coarse grains. American soybean meal also hovered around $450 US per tonne. While the world was preoccupied with the price of spaghetti, livestock and poultry producers were faced with how to scratch out a living from an ever-shrinking (and often negative) margin. One contributor to these historic grain prices was increased demand for grains by the emerging ethanol industry, whose growth of late has been spurred on by government policy and historic high oil prices.

There is ongoing disagreement among experts over the role and extent to which different forces (e.g., drought, market speculation, ethanol) contributed to these record prices. What few would dispute, however, is that over the past few years ethanol production has emerged from a fringe industry on the edge of Canadian agriculture to an important competitor for cereal grains in Canada and North America as a whole. The question in the mind of many producers is what to do.

Naturalist Charles Darwin once said “it is not the strongest of the species that survive, nor the most intelligent, but the one most responsive to change.” In other words, adaptability and flexibility (rather than size or deep pockets) are perhaps the most important qualifications to be a producer in the 21st century. To those who are more willing/able to adapt, adversity will seem less like a threat and more like a sign that it’s time to do things differently.

|

|

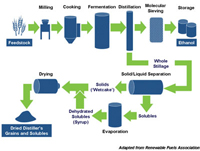

| Figure 1. Simplfied overview of the ethanol/DDGS production streams in modern ethanol plants. VIEW LARGER |

Challenges and opportunities, as the saying goes, are often two sides of the same coin. The challenge associated with increased competition for Canadian grain supplies for poultry producers is self-evident, but where is the potential opportunity in this situation? The answer: dried distiller’s grains and solubles. The goal of our monogastric nutrition research group at Alberta Agriculture and Rural Development, led by Dr. Eduardo Beltranena, is to fill in the information gaps to make DDGS a realistic and competitive alternative to more costly protein supplements (e.g., soybean meal) in poultry rations.

Dried distiller’s grains and solubles (DDGS) are a mixture of the solid and soluble residues from the fermentation and distillation system (Figure 1).

After milling, fermentation and distillation, the solid residue in the whole stillage is separated out into solid (referred to as “wetcake”) and liquid solubles fractions. The solubles fraction is concentrated by evaporating off excess liquid to produce a syrup. This is then added back to the wetcake and the mixture dried to produce DDGS.

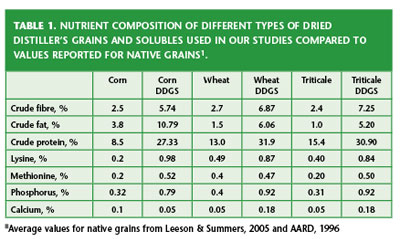

The resulting product has more concentrated levels of most nutrients compared to the native grain with the exception of starch, which is completely removed during fermentation/distillation (Table 1).

It should be noted that a side benefit of the fermentation process is that two-thirds of the phosphorus (P) in DDGS is available, which is roughly twice that of the respective native grain. This is due in large part to the destruction of phytate during the fermentation process. Phytate is the major form of P in plant-based feedstuffs and is digested poorly by pigs and poultry, who lack the necessary phytase enzyme. The implication is that diets that include DDGS would require less inorganic P supplementation, which could reduce both feed costs and P output from poultry operations.

|

|

| VIEW LARGER |

There are, however, several practical challenges to feeding DDGS. These include variability in nutrient content, storage and handling limitations (i.e., flow properties) in feed mill scenarios, limited information on maximum levels in practical diets and nutrient digestibility for DDGS types other than corn. Fibre content is another important consideration. During the fermentation process, valuable nutrients such as fat and minerals are concentrated, but unfortunately fibre is as well. Fibre generally impairs nutrient digestibility, especially for younger birds. Our research has focused on the last three challenges in this list. Recently, our group took a closer look at the feeding values of wheat, corn and triticale DDGS and the potential for low-cost processing to improve nutrient digestibility in a series of two experiments.

|

|

| VIEW LARGER |

The processing treatment compared in these studies was extrusion, either single- or twin-screw. An extruder operates similar to a meat grinder, where a screw shaft (or two) rotates within a barrel, exposing the material being extruded to pressure (i.e., heat) and shearing forces during passage. In theory, the shearing forces and heat experienced by the DDGS during the extrusion process should have positive consequences for amino acid digestibility. Shearing forces serve to disrupt the fibre in the feedstuff and heat forces proteins to unfold (i.e., denature). Both of these situations would presumably make proteins more accessible to digestive enzymes, which should increase the proportion available to the birds.

|

|

| VIEW LARGER |

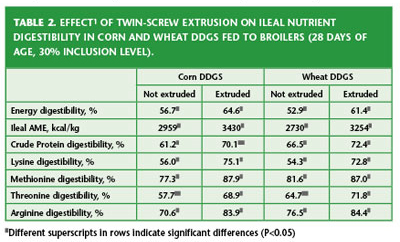

In our first experiment we tested the effect of twin-screw extrusion on nutrient digestibility of corn or wheat DDGS. Each type of DDGS (corn or wheat, extruded or not) was fed at either 15 or 30 per cent of the total diet to broilers on Days 7-14, 21-28 and 35-42 of the study. Ileal digesta was collected on Days 14, 28 and 42.

|

|

| VIEW LARGER |

Our results suggest twin-screw extrusion generally improved nutrient digestibility in both corn and wheat DDGS. Interestingly, while there were some minor differences in nutrient digestibility between non-extruded corn and wheat DDGS, nutrient digestibility in the extruded DDGS types was statistically the same (Table 2).

Based on some earlier work we did in pigs, we expected to see some improvement in amino acid digestibility, but the improvement we saw in lysine digestibility exceeded our expectations. Extrusion improved lysine digestibility approximately 35 per cent in both DDGS types. Digestibility improvements in the other nutrients were less dramatic, but still ranged between six and 19 per cent.

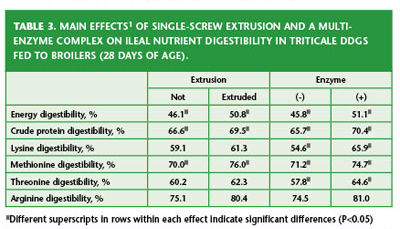

In the first study with wheat and corn DDGS, all diets contained a commercial multi-enzyme preparation (Superzyme DDGS, Canadian BioSystems) designed specifically for DDGS. In our second study we wanted to look closer at the effects of extrusion and the enzyme individually and in combination. To this end, in the second study we fed diets containing either 15 or 30 per cent triticale DDGS (single-screw, extruded or not), with and without the multi-enzyme complex. Test diets were once again fed to broilers on days 7-14, 21-28 and 35-42 of the study, with both ileal digesta and feces collected on days 14, 28 and 42.

In contrast to the improvements we observed in our first study, single-screw extrusion of triticale DDGS resulted in modest improvements in energy and crude protein digestibility and with the exception of methionine, little impact on amino acid digestibility (Table 3). In contrast, supplementing diets with the enzyme complex resulted in more consistent improvements. The enzyme complex improved ileal lysine digestibility in the triticale DDGS by 21 per cent and energy digestibility by 12 per cent.

The question you might be asking is why the differences between the two studies and even between wheat and corn DDGS in the first studies? Part of the answer might stem from differences between single- and twin-screw extrusion. Twin-screw extrusion is a generally more intense processing treatment (involving higher pressures), which in theory could do a better job of eliminating impediments to nutrient availability in feedstuffs. Another possibility is that the response to extrusion depends on DDGS type.

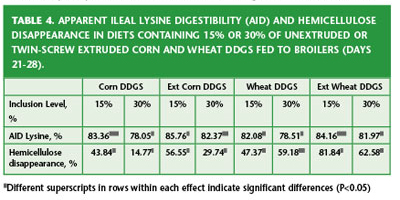

To explore this second possibility further let’s go back to study one and look at the disappearance of hemicellulose in each of the test diets (Table 4). Hemicellulose is a more degradable type of fibre (compared to lignin or cellulose) that forms part of the cell walls that surround starch granules (and associated protein) in the endosperm of cereal grains. Birds don’t produce the necessary enzymes to degrade hemicellulose, but microbes that live in the digestive tract do and are able to use it as an energy source via fermentation.

The results from our first study showed definite differences in hemicellulose degradation and lysine digestibility among the test diets (Table 4). When we looked at the relationship between lysine digestibility and hemicellulose disappearance we found that regardless of inclusion level extrusion increased hemicellulose degradation. However, there was a striking disparity between the two DDGS types in how well lysine digestibility correlated to hemicellulose disappearance.

For corn DDGS, there was strong positive correlation between the two factors, while for wheat DDGS the correlation was weaker and depending on whether DDGS was extruded or not, was either positive or negative. This tells us that much of the improvement in lysine digestibility in corn was related to fibre degradation, while in wheat there were other factors in play.

In summary, the take home messages from these two studies are that extrusion and enzyme supplementation (both alone and together) appear to improve nutrient availability in DDGS for broilers. The most dramatic improvements we observed were for lysine and energy digestibility, particularly where twin-screw extrusion was used in conjunction with a multi-enzyme complex designed especially for DDGS.

Learning more about DDGS nutrient availability and processing methods is central to finding a place for it in practical poultry feeding. To this end we are currently analyzing data from a separate performance study looking at the feasibility of graded inclusion levels of all three DDGS types, both extruded and not.

There is perhaps another characteristic that should be added to our earlier list of important prerequisites for being a 21st-century producer – optimism. A professor of mine once described a pessimist as someone who looks at a manure pile and sees only a manure pile. An optimist immediately grabs a shovel and starts digging into the pile in a desperate search for the pony that must have created the pile.

The “pile”, in the context of our discussion, is increased competition for and consumption of feed grains for ethanol production. The “pony” (for you optimists out there) is the potential of DDGS to replace more expensive dietary components and lower your feed costs – all while maintaining performance. Canadian poultry producers should take comfort in that our group at AARD is working hard to help them find that elusive “pony.”

For more information, contact Dr. Eduardo Beltranena 780-427-4567 or e-mail: eduardo.beltranena@gov.ab.ca

Print this page