Minimizing feed wastage

By Winfridus Bakker

Features Barn Management Cobb-Vantress Feed wastage SustainabilityAssessing the costs and impacts of feed wastage in poultry.

Small, round feeders are a new concept in feeders for broilers that may help minimize feed waste.

PHOTO CUTLINE: Cobb-Vantress

Small, round feeders are a new concept in feeders for broilers that may help minimize feed waste.

PHOTO CUTLINE: Cobb-Vantress Depending on which chickens are being produced, broilers or broiler breeders, up to 70 per cent of the cost can be allocated to feed. With feed costs continuing to rise, minimizing feed waste is more important than ever. However, feed wastage isn’t just a cost issue.

Feed waste can be a biosecurity issue as feed spills can attract wild birds, rodents, beetles (alphitobius) and other vermin that can carry pathogens onto the farm. Moreover, the environmental footprint is enlarged when resources, including water, energy, and land, used to produce feed ingredients and feed are wasted.

At the feed mill

Beginning at the feed mill, correct processing, preventing contamination and accurate formulation can help reduce feed losses. For example, incorrect processing can lead to pellets that are too hard, in which case birds may reduce or even refuse to consume the feed. Similarly, milling feeds to the correct particle size and uniformity is also important because birds may select larger particles and leave fines.

Contaminated feed can occur during the milling process in places such as the mixer (carry-over) and post-processing (dust contamination). Depending on the severity, contaminated feeds can be reworked, or batches may even be completely lost. In the case of rework, time, labour and energy costs are increased.

Consider potential spillage points, as spillage is a direct loss. Accurate weighing is also important, because when feed ingredients are not weighed correctly, feed formulation will be incorrect. This may not lead to lost batches of feed but could have negative impacts on flock performance. For this reason, calibrate scales on a regular basis to ensure that ingredients are included at the correct percentage.

Good quality raw ingredients should always be used to produce feed. Poor quality ingredients, such as corn contaminated with mycotoxins, will not only decrease the palatability, but also cause health issues. Rancid fats decrease feed palatability, reduce feed intake and absorption and induce poor uniformity. This is especially important in young chicks (first week), as a good start in rearing is important for attaining good performance metrics.

Feed transport, delivery and storage

To prevent contamination during transport, it’s important to ensure clean trucks are used. Carry-over from previous loads can contaminate feeds with additives such as coccidostats. Trucks should also be completely dry before filling to protect feeds from moisture, which can lead to mould growth.

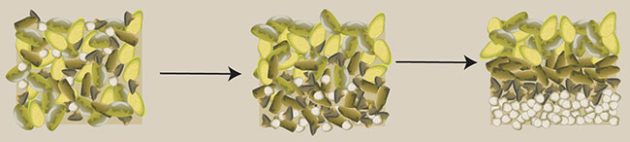

With mash feed, there is a possibility of particle segregation during transport, silo filing and feed distribution in the house. Particle segregation is an issue because birds may selectively eat large particles and leave fines leading to feed waste and possible nutritional intake deficiencies. This segregation occurs when there is a big difference in particle size, shape or density and the feed is shaken (Figure 1).

Additionally, coarser feeds are more prone to particle segregation than fine feeds. However, making the feed too fine also has issues. Therefore, with mash feed, the average particle size should range from 1,000 to 1,100 microns. At this range, particle segregation will be minimized and good gizzard development is still supported.

Feed storage is important to preserve quality and prevent contamination. Silos for feed storage should be well-sealed to prevent rodents, wild birds, insects and vermin from contaminating feed. Well-sealed silos are also important to prevent moisture and mould related issues.

It is good practice to have at least two silos available per house so that one silo can be completely emptied before adding a fresh batch of feed. This will help prevent feed from adhering and accumulating on the silo walls, which over time can become moldy. Likewise, it is important that feed is cooled properly before filling the silos. If warm feed is placed in the silos, condensation can occur leading to mold issues.

High corners on chain feeders are a good option to prevent feed spillage in chain feeder systems. PHOTO CREDIT: Winfridus Bakker, Cobb-Vantress

House environment and equipment management

Broilers

Considering that 70 per cent of the cost of raising broilers is feed, using the correct feeding system and ensuring that the feeding system is well maintained can be important for profits. There are several feeding systems available for broilers that work very well.

Recently, some European companies have been evaluating relatively small, round feeders that measure 18 centimetres in diameter. These feeders can be used for broilers up to four kilograms. Some field observations include:

- Flooding the feeders for day old chicks is easy and efficient.

- As of day two, no additional chick feeders are needed.

- Chicks cannot sleep inside, keeping the feed clean.

- Since the feeders are small, the birds empty them relatively quickly, activating the feeder line more often compared to large pans.

- Three levels of feed height in the feeder can reduce feed spillage.

- With these small feeders, the lighting program must be adjusted so that birds can eat ad libitum.

With broilers, a correct feed withdrawal program is also important and can help minimize feed wastage. Optimum recommended time for feed withdrawal is eight to 12 hours (beginning when birds do not have access to feed in the poultry house until shackling at the processing plant). Less than eight hours may result in excess feed and fecal residues in the digestive tract.

This is a waste, as the undigested feed will not be converted to meat. The excess feed residue will also cause yield, processing and contamination problems in the plant. Feed withdrawal longer than 12 hours causes the intestines to lose their tensile strength, making them easy to tear and rupture during evisceration at the processing plant. This will cause carcass and equipment contamination in the plant.

Broiler breeders

Feeder management is an important factor to control feed wastage. When using pan feeders, ensure that feeders are locked and do not swing. Swinging feeders not only make it difficult for birds to access feed but feed can also spill out of the pans if they swing.

To prevent spills when using chain feeders:

- Check for worn feeder troughs and spillage at the return to the feed hoppers. Perform maintenance and replace worn out parts.

- Set maximum feed levels in the troughs at one-third full. When feed levels are set too high, feed can spill out of the troughs when chains are running.

- Chain feeders with high corners prevent feed from spilling out of the trough, which is the best option.

Determining how much feed to order for the silos before a flock is transferred to the production farm or at the end of the production cycle is also critical to minimize feed wastage.

In most companies, the excess feed is taken out of the silos and moved to another flock, which incurs costs. However, on many occasions, the feed is wasted. Timing, logistics and calculating the correct amount of feed is important, so that the least amount of feed is present when the birds leave the farm.

Figure 1. Particle segregation in feed can occur when particle sizes vary considerably. Each time the feed is shaken, heavier particles will remain at the top and smaller, finer particles will fall to the bottom. When this occurs, birds may only consume the coarse particles on top and waste the fines. PHOTO CREDIT: Cobb-Vantress

Digestion and feed waste

Birds consume, digest and absorb the nutrients from the feed. Nutrients then are used for maintenance, growth and/or egg production. The efficiency of digestion and absorption is dependent on a healthy gut and good water quality and intake. For these reasons, poor gut health will reduce the bird’s ability to extract the nutrients, and, in turn, they will require additional feed to meet their genetic potential.

Broilers

Specific to broilers, a high feed intake and fast passage rate means good gut health is necessary for optimal feed digestion and nutrient absorption. Disruptions in gut health can cause feed to pass undigested and deposited in excreta, which negatively impacts costs and generally impacts the environment on both the feed and poultry sides of production.

To support good gut health, biosecurity programs are important to minimize pathogenic challenges. Other points to consider include making sure drinker lines are clean and provide fresh, cool water. Keep the litter dry with good ventilation and correct any dripping nipples or water line connections.

When temperatures are below the thermal comfort zone, birds must allocate energy to produce metabolic heat. If temperatures are too low, the birds will consume more feed to generate body heat to keep comfortable. Keep in mind that even with a pure heating fuel such as propane, it is still less expensive to heat with propane than with feed consumption.

Broiler breeders

For broiler breeders, it is important to follow the feeding programs recommended by your genetics supplier as overfeeding has consequences beyond feed waste. In addition to feed waste, over feeding birds can cause the following issues:

- Overfeeding pullets or having the wrong feed formulations can lead to extra breast muscle deposition and create complications such as early mortality after photo stimulation.

- Overfeeding hens can end up causing multiple ovulations, egg peritonitis, sudden death syndrome and a prolapsed cloaca.

- Overfeeding males will cause overweight males that have difficulties with mating. In this case, flock fertility can be negatively impacted.

Cost and environmental impact

Feed waste can come in many forms. There are direct wastage issues such as feed spills that can create losses beyond dollars including biosecurity risks. Use only good quality ingredients and preserve that quality by keeping feed stored under the correct conditions.

Producers must also consider feed consumption, digestion and absorption. That’s because feed that passes through the bird undigested has costs going all the way back to resources used to grow those feed ingredients.

Winfridus Bakker has 40 years of experience in poultry production operations. He joined the Cobb World Technical Services team in 2000. Winfridus is a Great Grandparent, Grandparent and Parent stock breeder specialist. He serves Latin America, New Zealand, Australia, and Central and Eastern Europe.

Print this page