For the last two years, Paul Wipf, poultry manager at the Baildon Colony located south of Moose Jaw in Saskatchewan, considered installing a free-run operation to replace the colony’s aging layer barn.

Baildon Colony fills gap in Saskatchewan

|

|

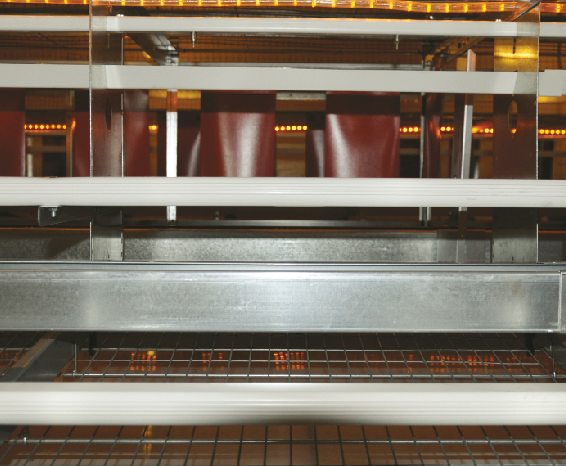

| The aviary features two levels of perches with grooves for easy gripping. Advertisement

|

For the last two years, Paul Wipf, poultry manager at the Baildon Colony located south of Moose Jaw in Saskatchewan, considered installing a free-run operation to replace the colony’s aging layer barn.

At an open house held at the colony on Jan. 16, Wipf clearly stated to attendees that the colony’s decision to produce free-run was not because they see the egg industry in Canada going in this direction, but because they wanted to supply the provincial market with a locally

produced product.

“We didn’t do this because we see this as the way of the future,” says Wipf. “We didn’t want the niche market here in Saskatchewan to be shortened, and didn’t want to see product coming from elsewhere.”

Wipf says that all members of the colony were part of the decision to install an alternative style of housing, and that a vote was taken, with 100 per cent of members voting yes.

|

|

| Baildon Colony poultry manager Paul Wipf says that the free-run aviary system has presented some management challenges but he’s already learned so much by observing the birds.

|

|

|

|

| The aviary showing a ladder to allow birds access to the second tier.

|

|

|

|

| Two scales are present on each side to weigh the birds to adjust feed.

|

Prior to the Baildon Colony, Saskatchewan only had one operation producing a commercial free-run product, after the province’s only egg processor, Star Egg, developed a niche market. However this operation is too small (5,000 birds) to fill demand, leaving Star Egg with a gap to fill.

The Baildon Colony chose to install an aviary housing system manufactured by Hellman Poultry Equipment, after speaking with the poultry manager at New Rockport colony in Alberta. New Rockport was the first operation in North America to install an aviary, implementing the Hellman system, which the company says meets or exceeds European Union (EU) regulations.

Baildon tore down their old pullet barn and built a new split barn to house the aviary. The former layer barn is currently being gutted with plans to convert it into a floor-rearing pullet barn, which Wipf says should be ready in the fall.

Baildon installed four rows (each 280 feet long) of aviaries. Each row is two tiers high, consisting of laying nests behind plastic curtains and two rows of perches that have grooves to allow for easy gripping. One row of perches runs along the bottom of each tier, the other above the feeder chain so that the rears of the hens hang over and no fecal material contaminates the feed.

Running along the bottom edge of each aviary tier near the egg belt is a stainless steel bar that acts as a “landing strip” for flying birds, and several wire ladders are placed along each row from the floor to the bottom of the top tier to allow birds to walk up to this level.

Under each tier is a manure belt, with the exception of the “gutter” below the bottom tier of each row, which has a manure scraper to collect dust, feathers and some droppings from the birds as they are walking on the floor. Access to this area can be opened up to allow more square footage, and can be closed off during the night while the birds are sleeping. Plastic netting has been placed from the top tier to the ceiling to prevent hens from jumping up into this region.

All lights in the barn are on winches, allowing proper placement of the lights so that reflected light shines on the curtains, which makes the hens feel safe while in the nest. LED rope lighting has also been installed along the length of each aviary at the top over the feed chain.

The barn utilizes roof ventilation instead of tunnel ventilation to maximize square footage, with inlets running on each side of the barn. The system also features two hanging weigh scales per side that can sense how many birds are on it at one time. This will provide Wipf with accurate bird weights so that he can manage feed intake, which is important since the aviary will house brown birds, which “tend to gain weight,” he says. These scales can be moved to different areas, depending on where the birds are most active, he says.

The aviary barn can house 20,000 birds, although the colony only has quota for 16,000 birds, allowing them the option to expand. This setup allows for 1.5 square foot/bird.

On Jan. 19, 10,000 floor-raised pullets reared in Manitoba were placed in the aviary system at Baildon Colony. Several weeks later, when asked how things were going Wipf said the “barn looks so good with the birds in it. The birds are so happy – when I turn the lights on in the morning they fly and run around, just like wild birds in the trees in springtime.”

Wipf says “it’s so different” from the former system and he finds it to be both interesting and challenging. But he was ready for the challenges and seems to take them in stride. “I knew it was not going to be like conventional housing,” he says. “Management of the birds requires watching the birds and their behaviour.”

He says that in the first few weeks he “definitely” spent more time observing the birds until he got to know them and what they needed.

His powers of observation have already been tested. One of his first challenges was determining why the birds weren’t eating enough. The LED lighting, which was turned on before the regular lights went out and kept on for an additional 15-20 minutes to signal the hens to come into the aviaries and roost on the perches for the night, didn’t seem to be having the correct effect on the birds. Wipf says he went into the barn to check and see if the birds were roosting and was surprised to see many still roaming the floor and being active.

This made him think that perhaps the birds couldn’t really see the LED lighting properly within the aviary. So, he decided to keep the LED lighting on all day, which seemed to do the trick. Wipf believes that by keeping the LED lights on all day, the birds can see the feed and water much better in the aviary and now when the regular lights go out, all of the birds are roosting.

To solve the other challenge he has faced so far, Wipf utilized the experiences of New Rockport, consulting with the poultry manager there. Into the first week or two of lay, Wipf says he’s having “a few too many” broken eggs than he’d like to see. After discussing it with his New Rockport colleague, Wipf says it appears some of the birds are laying eggs while on the top perch, creating too far a distance for the eggs to fall and hence creating cracks.

But Wipf isn’t worried, and says that he’ll have to “wait and see” what new challenges, if any, arise. “I’ve already learned so much.”

Wipf says it’s now clear to him that once the new pullet barn is ready and he is raising his own pullets on litter, he will need to “facilitate a similar environment” for them so that they are better prepared for the aviary. This will include installing LED lighting above perches so that the pullets are familiar with it, as well as ladders to get them used to travelling at different levels. These will be manufactured by members of the colony.

Print this page