Precision livestock farming

By Karen Dallimore

Features HealthNanotechology uses tiny biomarkers to detect subclinical signs of disease at the molecular level in a non-invasive manner.

Suresh Neethirajan calls the agricultural revolution towards using nanotechnology ‘precision livestock farming’, a progressive movement over the past decade where technological advances are being used to save time.

Suresh Neethirajan calls the agricultural revolution towards using nanotechnology ‘precision livestock farming’, a progressive movement over the past decade where technological advances are being used to save time. When a farmer enters the barn, he or she hears first, then sees, then smells the environment. Nanotechnology sensors can detect all of these parameters, providing novel solutions to practical issues in poultry health.

Suresh Neethirajan is an assistant Professor and the director of the BioNano laboratory at the University of Guelph. He calls this agricultural revolution towards using nanotechnology ‘precision livestock farming’, a progressive movement over the past decade where technological advances are being used to save time – the time to test results or make management decisions.

The ultimate goal of precision livestock farming is to transmit real time data related to health parameters using a combination of mobile phones and Internet to enable the end user to monitor and track flock health to enhance the productivity and welfare of the birds. The data is then used to proactively predict and prevent disease. This strategy is made possible by using nanotechology, which, in turn, uses tiny biomarkers to detect subclinical signs of disease at the molecular level in a non-invasive manner.

Neethirajan uses the example that preventing the spread of Avian Influenza (AI) might be the best way to keep the disease under control. Using nanotechnology, he is developing a hand-held AI virus detection tool that will be able to differentiate and classify different strains of the AI virus – information that is crucial to optimize management strategies to treat and help prevent the spread of the disease. The tool will be able to replace the current laboratory RT-PCR analysis that can take from six hours to three days.

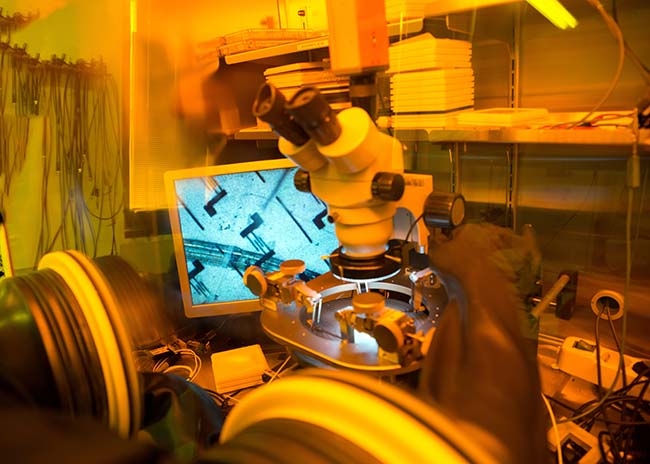

Two types of nanotechnology are being investigated for this AI detection tool. The first type uses an optical sensor device, where light is reflected off specific nanomaterials, which bind in specific ways to proteins on the surface of the virus, fluorescing differently to allow identification of the strain

of the pathogen. This information can be gathered in real time and records can be transferred through an android app to the entire value chain or veterinarians as required.

Another option is an electrochemical type of sensor, similar to a handheld glucose meter. Just a droplet of blood can be read immediately using nanomaterials that focus on the virus pathogen rather than the chemical biomarker.

Both optical and electrochemical options are being investigated, mainly to ease the interfacing with the smart phone and Internet for real-time transmission of data. Each of these modules has unique advantages, while optical seems to be easier to adapt, mainly because of the presence of cameras in the phones.

At this stage the research focus is on multiplexing – refining the biosensor to identify multiple strains of the AI virus from a single drop of blood.

Following a similar predictive and preventative approach, Neethirajan is also developing an Internet of Things (IoT)-based poultry monitoring telemetry system that will monitor bird health in a non-invasive manner, looking for subtle signs of disease that can be addressed proactively.

With this telemetry system, a loonie-sized sensor placed on the bird will detect movement, monitor skin temperature and other biomarkers such as relative humidity, temperature, carbon dioxide, methane and ammonia levels, in real time fashion that could then become predictors of disease. This technology would not be feasible to monitor thousands of birds individually, but the data from sample birds in a flock can be applied to mathematical models to generate holistic predictions of flock health.

Nanotechnology can also supply micro electrical mechanical systems (MEMS) – based sensor probes that can monitor blood flow in a non-invasive manner. Even sound can become a predictor of disease because the sound of a healthy chicken differs from a bird under any kind of stress. Integrating this vocalization with movement gives a more holistic picture of the health of the bird.

More work is needed regarding practical application before this technology can be valid for on-farm use. For example, wearable sensors need to be lightweight and made of biological materials where possible so that the birds don’t peck at the ‘foreign’ object. Where sound is measured, random barn noise needs to be excluded from detection. Wireless technology doesn’t work in all barns in all locations, and adaptations will need to be made to accommodate differences between caged and cage-free systems. Meanwhile thresholds of disease are being better established through mathematical prediction models and apps for reporting data are being refined.

Print this page