Laying the Groundwork

Kristy Nudds

Features Equipment Poultry Equipment Research Welfare Alternative poultry housing Animal Housing Poultry Research ResearchNew research chair is examining the welfare of hens in alternative housing systems

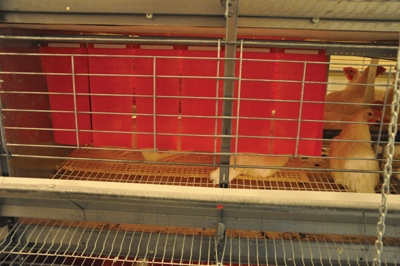

Dr. Tina Widowski, EFC’s chair in poultry welfare research, is examining how well hens use furnishings (such as nesting areas, above) in enriched cage systems.

Dr. Tina Widowski, EFC’s chair in poultry welfare research, is examining how well hens use furnishings (such as nesting areas, above) in enriched cage systems. Pressure from animal rights groups to improve the welfare of laying hens has resulted in significant legislative changes in Europe and California with respect to layer housing. Welfare concerns have also caught the attention of consumers and retailers in the rest of North America, and egg producers are now faced with providing a better quality of life for the hens, while still providing a product that meets food safety standards and that is economically feasible, not only for their own bottom line, but also at the grocery case.

Consequently, many producers in Canada are considering installing (or have already installed) alternative housing systems, such as enriched cages or aviaries, on their farms. Although existing research in Europe and North America shows that these alternative systems provide many welfare benefits, many questions still exist with respect to cost of production, how best to optimize bird management in each different system, and how bird density and group sizing affects welfare and costs within the systems.

That’s why nearly two years ago, the Egg Farmers of Canada (EFC) decided that it wanted to support a research chair in animal welfare, according to EFC’s manager, corporate and public affairs, Bernadette Cox. The organization spent some time examining the research work and meeting with scientists in the field. Cox says that CEO Tim Lambert and EFC chair Peter Clarke felt that Prof. Tina Widowski of the University of Guelph was the person they were looking for, and announced that she was the new EFC chair in poultry welfare in May 2011.

Widowski, who is based in the Ontario Agricultural College’s Department of Animal and Poultry Science, was chosen in part because she has an impressive record of research in a variety of welfare issues, is actively engaged with other scientists in North America (including the University of Michigan and the Poultry Welfare Cluster, also based at the University of Guelph), and is the leader of North America’s largest group of animal welfare scientists as director of the Campbell Centre for the Study of Animal Welfare.

Cox says that, although EFC is not directing the type of work that is being done, Widowski does inform the organization of her progress and seeks opinions about what areas of welfare research are the most pressing for Canadian egg producers.

The funding partnership between the University of Guelph and EFC formally began in March 2011, and will continue through January 2017.

Not only will the partnership benefit egg producers, but it will benefit the University of Guelph as well, says Widowski. The funding has allowed for the hiring of a junior faculty member (currently underway) and has provided opportunities for several graduate students, who will become part of the next generation of technical experts in animal welfare. The university’s poultry unit at the Arkell research station has also benefited, with new, up-to-date equipment, she says.

Equipment

Four rooms in the poultry unit were cleared to accommodate the new housing systems, all of which are manufactured by Farmer Automatic (FA), a Germany-based company that has a partnership with Ontario-based Clark Ag Systems Ltd.

One room houses FA’s pullet-rearing floor system, the Portal Rearing System, while another of the rooms houses the Loggia system, the company’s layer aviary. The other two rooms house the Layer Cage ECO, FA’s enriched cage system, which has been designed according to the regulations for layer housing set forth by the EU and that came into effect Jan. 1, 2012.

The equipment was installed over the summer of 2011, and the university and Clark Ag Systems Ltd. held an open house in mid-September for producers and industry representatives prior to the arrival of the birds.

What’s Being Studied

Widowski’s first project is to study the behaviour, welfare and production parameters of layers housed in the enriched system at two different densities — 80 square centimetres/bird and 116 square centimetres/bird (the EU regulation). The reason behind this, says Widowski, is that if the industry is faced with a “transition” period with respect to bird densities (as may happen in the U.S. with the proposed agreement between the Humane Society of the United States and the United Egg Producers), it’s important to know what production levels are achieved with smaller densities because more barns will be required to match the current production levels of conventional systems.

Two different cage sizes are being utilized. The larger cage is double the size of the smaller, and the amenities (i.e., “enrichments” such as nest area, perches, scratching area and floor space) are also doubled. To examine the effect of density in each cage size, the smaller cages have groups of 28 or 40 birds, and the large cages have groups of 55 or 80 birds.

What’s of interest to Widowski is how well the birds are using the enrichments. Decades of research have shown that hens are highly motivated to perform/express behaviours that are natural to them, which conventional cages do not allow. Four key behaviours have been identified as being important to a hen — foraging, dustbathing, nesting and perching. Enriched systems provide the tools to allow hens to express these behaviours, but Widowski says that although we like to give ourselves a pat on the back for giving the birds something to perch on and a nesting area, it’s important to make sure that these behaviours are actually being supported by the amenities provided.

For example, what is not known is whether the nesting area is sufficient for the number of birds in each cage, she says. She and her research team have observed that about 10 to 20 per cent of eggs are being laid outside of the nest area, with the majority of these laid in the scratch area. Widowski says she would like to know whether this is because the nest space is insufficient, or because, like the nest area, the scratch area is in a corner of the cage and this offers the birds the same seclusion they would have in the nest.

Methodology for data collection has been completed and Widowski says she has a team of graduate students ready to start collecting and quantifying welfare and behaviour data. Each room is equipped with video cameras, and the students will be examining bird behaviour on the videotape as well as through live observation.

One student will be looking at nesting in depth — where the birds are laying, why this varies and whether social competition for nesting is a problem, she says. Another student will be examining dustbathing and foraging behaviour.

This student will be looking at how well the birds use the scratch area, which is a smooth plastic mat (Widowski opted not to use an astroturf-type mat, as it gets full of manure and she says many producers are moving away from these). Because enriched systems do not provide litter or other material to stimulate foraging and dustbathing as the aviary/free-run housing systems do, this behaviour is being triggered by having a feed auger over the scratch area that provides 20 grams of feed 10 times throughout the day. The effectiveness of the auger approach will also be examined.

A third student gets the “night shift,” says Widowski. She will be looking at how well the birds are using the perches, and how the perches are being used. Widowski is interested in answering some previously unanswered questions, for example: Are the birds conservative in perching? Is it the same birds perching? Is there a specific spot that they always go to? Eventually, says Widowski, she will be comparing the bone strength of the keel and leg bones in perchers versus non-perchers.

Also of interest are activity patterns — the birds have a lot more space, but do they use it, and how? She will also be looking at the pattern of time the eggs are being laid. She says that depending on the strain of hen (the birds in the current study are Lohmann), some will lay their eggs in more compressed or wider windows of time, which will in turn affect the competition and pressure on the nesting area at certain times of the day. If the window of time is compressed, “it’s like a big family wanting to use the bathroom at the same time,” she says.

Parameters such as egg production and feed intake are being measured and will be compared to birds housed in conventional cages located in another room at the Arkell research station.

Research methodology is near completion for the aviary system, and later this spring chicks will be placed into the Portal Rearing System. Widowski says she will be examining how pullets raised in this system adjust to the aviary. Once in the aviary, she plans to look at how load-bearing exercise and the opportunity to fly increase bone strength.

Widowski regularly updates EFC’s research committee and board of directors on the progress of the research. Cox says that results from the research will be summarized and communicated to producers either through the provincial boards or directly from EFC by way of a mailing or Internet posting.

Open House

Clark Ag Systems Ltd. hosted an open house at the University of Guelph’s Arkell poultry research station in September 2011 to allow producers and industry representatives to see the Farmer Automatic Portal Rearing System, Loggia system and Layer ECO system. Dr. Tina Widowski and representatives from Clark and Farmer Automatic were on hand to answer questions and show attendees how the systems operate.

To view videos of the Layer Cage ECO and Loggia systems, visit www.canadianpoultrymag.com (see this article under “current issue”) or YouTube (put “TheClarkCompanies” in the search bar).

Print this page