Maximizing Corn: Feed value consistency can vary

By Dr. Milan Hruby Technical Manager Danisco Animal Nutrition

Features New Technology ProductionFeed value consistency can vary

Poultry producers,

nutritionists and feed manufacturers tend to regard corn as an

ingredient which is consistent in terms of nutritional value,

regardless of where in the world it is grown and under what conditions.

This is a myth.

| Poultry producers, nutritionists and feed manufacturers tend to regard corn as an ingredient which is consistent in terms of nutritional value, regardless of where in the world it is grown and under what conditions. This is a myth. During the last four years Danisco Animal Nutrition has conducted Advertisement

ASSESSING VARIABILITY

Feed manufacturers and Danisco’s analysis of 222 corn samples harvested in 2007, grown in 17 |

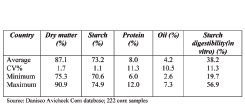

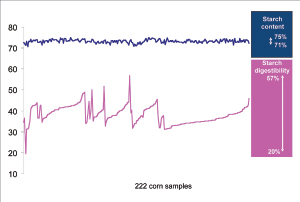

Since starch contributes around 65-70 per cent of the energy value of corn, it is interesting to note that analysis of the 222 corns highlighted the fact that both the starch content and starch digestibility can be highly variable between batches of corn (refer to Figure 1).

VARIABLE PERFORMANCE

Consistent bird performance is the goal of the poultry producer. Since a typical corn-soy diet contains 65-70 per cent corn, significant variation in the nutritive value of corn will clearly lead directly to variation in bird growth and feed conversion.

|

|

|

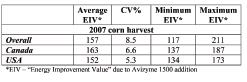

| Table 1. Corn analytical values from harvest 2007 | Table 2. Enzyme addition improves the energy digestibility of corn |

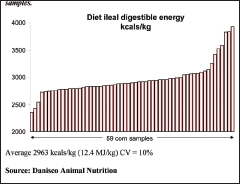

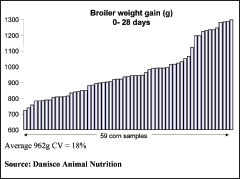

Danisco set up a research program to establish the effect of corn variability on bird performance. The research program involved obtaining 59 different corns, from 13 countries worldwide representing U.S., South America, Europe and Asia. These corns were included in different batches of feed, formulated to contain 55 per cent of each corn sample in an otherwise constant diet. The diets were fed to broilers and the ileal digestible energy of each diet and liveweight gain of birds were measured at 28 days.

Ileal digestible energy varied substantially between samples from 2361 kcals/kg feed (9.9 MJ/kg feed) to 3930 kcals/kg feed (16.4 MJ/kg feed) (Figure 2) and bodyweight gain at 28 days ranged from 747 g to 1301 g (average 962 g) (Figure 3). Since all diets were otherwise identical in composition, including source of ingredients except for the corn, any variation in ileal digestible energy and bodyweight gain between the birds could be directly attributed to variation in corn feeding value.

|

|

|

| Figure 2. Ileal digestible energy in broilers fed diets containing different corn samples | Figure 3. Weight gain of broilers fed diets containing different corn samples |

IMPROVING CORN QUALITY

Proven to be effective in more than 70 research and commercial trials, Danisco’s enzyme combination (Avizyme 1502), a unique blend of xylanase, amylase and protease, improves the rate of starch digestion within the small intestine. Amylase, a starch digesting enzyme, helps the bird to digest more of the starch in the corn. Since the major source of energy in corn-based diets is starch, increasing starch digestibility means an improvement in energy digestibility. Protease, a protein digesting enzyme, breaks down proteins that bind starch. The bound starch is then released and more available for digestion by both the bird’s own amylase and Avizyme 1502 amylase. Xylanase breaks down the fibre-rich cell walls, releasing enclosed starch, again increasing its availability for digestion.

The net result is that the amylase, protease and xylanase in Avizyme 1502 work in combination to improve starch digestibility and hence increase corn energy digestibility.

|

| Figure 1. Starch content and in vitro starch digestibility can be highly variable between batches of corn.

|

The degree to which the enzyme blend can improve the energy digestibility of corn is expressed as an Energy Improvement Value (EIV). Danisco identified that several factors influence the degree to which the enzyme blend can improve the energy digestibility of corn. These include starch, protein and oil content, starch digestibility and protein solubility index (which provide an indication of the degree of protein binding with other nutrients in corn). These factors are measured routinely in the Danisco laboratory to assess the EIV of different corns.

Table 2 summarizes the average EIV of the 222 corn samples harvested in 2007, as well as the key countries, U.S. (67 corn samples) and Canada (48 corn samples). The average EIV for all samples was approximately 157 kcals/kg, ranging from 117 kcals/kg to 211 kcals/kg.

MORE PROFIT

In broiler production systems, feed is the biggest single cost and profitability depends on the relative cost and nutritive value of the key ingredients. As indicated, corn is inherently variable and therefore maximizing its nutritive value and minimizing its variability can significantly improve the economics of broiler production.

The knowledge gained from our research into corn variability led directly to the development of a unique service – Avicheck™ Corn. The service enables broiler feed manufacturers to optimize their use of Avizyme 1502, according to the quality of corn used in the feed formulation. The service includes a unique laboratory assay that estimates how much Avizyme 1502 can improve the ME [of corn, reported as the “Energy Improvement Value” (EIV). Including Avizyme 1502 and the new higher energy corn into the feed formulation provides opportunities to reduce feed costs. Typically the higher energy corn replaces some more expensive high-energy ingredients, such as fat or oil.

The service also includes an economic model that estimates the value of the enzyme blend to the broiler producer accruing from both reduced feed costs and improved broiler bodyweight uniformity. The financial benefits are very attractive. For example, the current net financial benefit to a Canadian broiler producer from using the enzyme blend, as predicted by Avicheck Corn, is approximately $ 5.00 Cdn/tonne of feed. This currently equates to an additional $1.1 million Cdn of income annually for a broiler producer processing 1,000,000 birds a week. Avizyme 1502 is a flexible product that can be used in diets containing both corn and wheat.

It seems that high corn and fat/oil prices are here to stay for the foreseeable future. For commercial broiler producers looking to maximize production efficiency and improve bird uniformity these latest advances in enzyme technology represent an exciting and significant step forward.

Enzymes and Poultry Feeding According to a recent paper in the International Journal of Poultry Science, a large number of enzymes – such as carbohydrases, proteases, phytases and lipases – are used, most often in combination in feed preparations, to increase nutrient digestibility, remove antinutritional factors (for example, those from mycotoxins), reduce environmental impacts from manure, and improve overall production efficiency. Economic and Environmental Impact of Using Exogenous Enzymes on Poultry Feeding, International Journal ofAccording to a recent paper in the International Journal of Poultry Science, a large number of enzymes – such as carbohydrases, proteases, phytases and lipases – are used, most often in combination in feed preparations, to increase nutrient digestibility, remove antinutritional factors (for example, those from mycotoxins), reduce environmental impacts from manure, and improve overall production efficiency. Two economic approaches to enzyme usage are commonly employed when considering their inclusion in a diet formulation. The first is to supplement a standard diet with enzymes, the goal being to enhance overall performance. The second use is to manipulate the diet formulation by reducing nutrients (or utilizing lower quality feedstuffs) and adding enzymes to restore nutritional value, equal to a standard diet. |

Print this page

Two economic approaches to enzyme usage are commonly employed when considering their inclusion in a diet formulation. The first is to supplement a standard diet with enzymes, the goal being to enhance overall performance. The second use is to manipulate the diet formulation by reducing nutrients (or utilizing lower quality feedstuffs) and adding enzymes to restore nutritional value, equal to a standard diet.

Two economic approaches to enzyme usage are commonly employed when considering their inclusion in a diet formulation. The first is to supplement a standard diet with enzymes, the goal being to enhance overall performance. The second use is to manipulate the diet formulation by reducing nutrients (or utilizing lower quality feedstuffs) and adding enzymes to restore nutritional value, equal to a standard diet.