“My, how you’ve grown…”

By Dr. Valerie Carney

Features Business & Policy Farm BusinessBroiler growth and performance has come a long way

Broiler growth and performance has come a long way in the last 50 years – and it’s been achieved without the use of hormones

If Only I had a Nickel….

If Only I had a Nickel….

As a poultry scientist, I often think, “If only I had a nickel for every time I was asked about hormones in chicken.” It is quite satisfying to be able to respond that the poultry industry does not feed or inject hormones. At times the conversation ends with a look of distrust and a change of subject, but more often than not it is followed with the classic question: “Then…why are they so big?”

“It’s genetics,” I answer.

History of Poultry Genetics

The history of poultry domestication dates back to 1000 B.C., but poultry as an industry was slow to develop initially. During the 19th century, poultry breeding was largely a cultural phenomenon that focused primarily on feather and form with little interest in egg and meat production. As interest in poultry began to move towards its suitability as a food source, two significant events of the 20th century enabled the expansion of the poultry industry and fueled its progress: the rediscovery of Mendelian principles of heredity, and the invention of a reliable trap nest to record egg production.

Prior to the 1930’s, production birds were mass selected and bred as pure lines without pedigree records. Selection focused on increasing egg production and the poultry meat industry was generally a byproduct of the egg industry. Although advances were made in production traits, progress was slow. The use of pure lines did not capitalize on the effect of heterosis or hybrid vigor.

Between the 1930s and 1950s crosses of pure lines were used to improve fitness and reproduction. The use of pedigrees allowed for removal of unwanted traits and promotion of desirable traits to the next generation while maintaining genetic variation. Modern broilers are descendants of a Cornish and White Plymouth Rock cross that, by means of genetic selection, has resulted in the development of broilers with astounding production and breeding performance.

Poultry breeding in the 21st century requires knowledge of economics, science and consumer preferences. Market demand drives product development and thus breeding programs. The commercial broilers of today are a result of three or four way crosses. Although important economic traits are measured on pure lines, much of the progress in production traits takes advantage of the combining ability of these crosses.

The time line between pedigree selection and commercial broiler production is three to five years, and thus primary breeding companies are obligated to recognize field performance and market signals that help to predict requirements of future products. The basic principles of breeding have not changed. The primary breeders continue use to evaluate genetic potential through various performance measurements of an individual and its relatives. Birds that exhibit the best genetic potential to meet the product requirements are allowed to naturally mate to produce the next generation.

Adaptation of new technology and application of science combined with powerful statistical methods and computing power have allowed the poultry industry to make more informed decisions about the most suitable candidates for pedigree populations.

Drivers of Change

Over the last 50 years, there has been a significant change in the poultry industry. As consumer demands changed, the poultry industry responded by providing new products to meet these demands.

This responsiveness of the industry has had a significant effect on the steady increase in poultry consumption of the last few decades. In the 1960s poultry consumption in Canada was 9.5 kg per person. By 2004, per capita poultry consumption increased to 30.4 kg .1

Both the form in which poultry is consumed and the location of purchase has also changed significantly. Fifty years ago, almost all chicken was purchased as a whole bird to be cooked at home. Today, whole bird production has dropped below ten percent of total production, as ninety percent of broilers processed today are sold as pieces or further processed products. Various market sectors have evolved to include retail, fast food, full service restaurants and hotels/institutions.

These market changes have significantly impacted breeding program objectives. Consequently, efficient white meat yield has become the most economically important driver of selection programs.

Genetic Progress

The poultry industry is one of the most efficient sectors in all of agriculture. To meet changes in consumer preferences over the last 50 years, poultry production has experienced phenomenal improvements in growth and efficiency. Much of this progress can be attributed to the reproductive ability of poultry, the adoption of new and advancing technologies and industry structure.

But exactly how far has the industry come with respect to growth and efficiency in the past five decades? My colleagues Brenda Schneider and Martin Zuidhof and I decided to evaluate the change in poultry production and meat quality traits over the last 50 years in a recent study performed at the Poultry Research Centre at the University of Alberta.

Examining Broilers of Yesterday and Today

Examining Broilers of Yesterday and Today

To evaluate genetic progress over the last 50 years, modern broiler strains were compared to historical strains. Fortunately for us, poultry scientists had the foresight to develop random breeding populations of broilers from broiler strains that existed at various points in time.

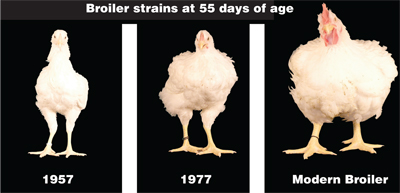

In our experiment, two random bred populations representing 1957 and 1977 broilers and modern broilers were used to examine genetic progress in growth, efficiency, yield, and meat quality (previous page). The 1957 broiler strain was a randombred population that descended from the Ottawa Meat Control Strain. A random sample of this strain was sent to the USDA Regional Research Station in Athens, Georgia and renamed the Athens Canadian Randombred Control.2 A small subpopulation of the Athens Canadian Randombred Control has been maintained at the University of Alberta for the past 18 years.

In 1977, the ARC Strain 20 was initially comprised of five sire line commercial stocks that were crossed to make four-way crosses and then allowed to randomly breed in subsequent populations.3 This random bred strain was developed in Ottawa at the Animal Research Centre (ARC) and a subpopulation has been maintained at the University of Alberta for nearly two decades.

Throughout the eight-week experiment, all three strains were fed a modern broiler ration. Individual body weight and feed consumption were measured on a pen basis weekly. A sample of birds from each strain was processed twice a week to measure growth of a variety of body parts and organs.

Why the Poultry Industry Doesn’t Need Hormones

Growth of an organism is a dynamic process of development of various parts, organs, tissues and physiological systems. Since bodyweight is easily measured, it is the primary trait measured to assess growth. However, genetic selection for growth can have negative consequences since the rate of development of one part of the body may be altered relative to the rest of the body.

The timing of selection can also affect these relationships between different parts of the body. In 1957 many commercial strains of broilers were available with a range of bodyweight performance. Broilers were grown for eight to 10 weeks to achieve bodyweights ranging from 0.9 to 1.6 kg and were marketed as whole birds. Likewise, modern day broilers are processed over a range of body weights depending on the final product. Primary breeders have employed a variety of selection strategies to target more precisely narrow weight specifications of various products.

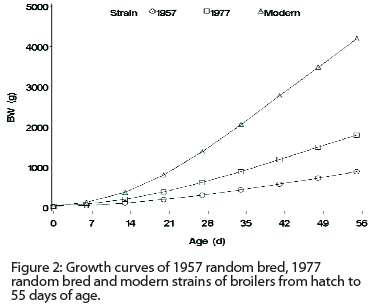

In today’s market most broilers in Canada are processed between 35 and 42 days. As shown in Figure 2, genetic selection over the last 50 years resulted in the modern broiler being 200 per cent heavier than the 1977 strain (1205 g) and more than 400 per cent heavier (2787 g) than the 1957 strain (592 g) at 41 days of age. A research trial in 1991 showed that the contemporary broiler was 250per cent heavier than the 1957 strain.4

Given these differences in bodyweight, it is not surprising that these strains had significantly different rates of gain. Modern boilers gained an astounding 100 g/d at 41 days of age. The 1977 strain and the modern broiler strain reached their maximum rate of daily gain around 48 days of age at 43.7 g/d and 104 g/d, respectively.

However, the 1957 strain had increases in the daily gain to 55 days of age at a rate of 23 g/d. It is difficult to know if the rate of gain would continue to increase given that the trial was completed at 55 days. Due to increasing growth potential, selection for body weight that matches market weight has progressively reduced the market age of broilers.5 Increasing rates of gain in more modern strains can largely be attributed to increased feed intake and improved feed conversion efficiency.

Improvements in Feed Efficiency

Improvements in Feed Efficiency

Since feed is one of the most expensive inputs in poultry production, primary breeders have dedicated much of their research and selection efforts to improving feed conversion efficiency. However, selection for this trait is not straightforward, as management and environmental conditions will have a significant impact on it. Scientific knowledge of broiler nutrition aided in the development of broiler diets that support fast growth and high yield while reducing feed costs.

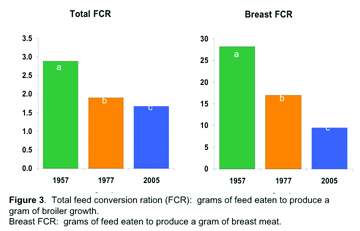

The greatest improvement of feed conversion efficiency occurred in the 20 years between 1957 and 1977. The 1957 strain required 29 g of feed to produce 100 grams of broiler growth to 41 days, compared to 19 g and 17 g required for the 1977 and Modern broiler strains (Figure 3).

Significant progress from 1957 to 1977 can be attributed in part to a few factors. Genetic selection during the 1960s was limited to a few traits such as body weight and feed conversion, and thus significant progress in these traits was possible.

However, by the mid 1970s it was apparent that selection for growth had a negative impact on the reproductive performance of broiler parent stock. The incidence of metabolic diseases such as ascites and skeletal deformities such as leg and walking problems in broilers also increased.

To address this problem, selection programs over the last three decades have evolved to produce a more balanced bird by selecting for the improvement of multiple traits in areas of growth, yield, efficiency, reproduction, skeletal and cardiovascular fitness, immune function and meat quality, just to name a few.

However, by selecting for more traits at one time, the rate of progress for any one trait is potentially lower. But new statistical methods and more powerful computing ability have helped to maintain the rapid rate of progress, especially in economically important traits. Due to the competitive nature of the poultry industry, traits such as white meat yield will continue to be selected for heavily.

Since feed is such a costly input and white meat yield is the highest profit output of broiler production it is interesting to examine how the efficiency of production of white meat has changed. It is remarkable that through 50 years of genetic selection the amount of feed required to produce 100 g of white meat has been reduced to one third the amount required in 1957. The modern broiler strain required 9 g of feed to produce 100 g of breast meat compared to 16 g for the 1977 strain and 27 for the 1957 strain

(Figure 3).

Yield

Astonishing progress has been made with respect to white meat yield because this trait has a high heritability (meaning that its variation is attributable to inherited genetic factors, not environmental factors). Traditionally, yield was indirectly selected for using a subjective conformation score. This conformation score was used to improve the visual appeal of the whole carcass. However, as product type has shifted away from whole carcasses to deboned breasts and raw material for further processing, conformation has become a secondary trait to yield.

Today, individual yield performance is assessed using ultrasound to measure muscle thickness. These measurements may be combined with traditional conformation scores and yield information of families to better enable geneticists to evaluate pedigree populations. Figure 4 shows the changes in white meat yield over the past 50 years. By 41 days of age, yield of the modern broiler was 19.0 per cent of full-feed liveweight. This is almost twice the yield of the 1957 and 1977 strains, which were 10.9 per cent and 11.1 per cent, respectively.

It is not surprising that yield (as a percentage of liveweight) did not change between 1957 and 1977 since whole carcass yield was selected for and not white meat yield specifically. Yield of the pectoralis major (breast muscle) almost doubled from 1977 (8.3 per cent) to 2005 (15.4 per cent), whereas yield of the pectoralis minor (tender) increased modestly from 2.7 per cent in 1977 to 3.5 per cent in 2005.

Conformation scores measure the degree of fleshing and since it is not possible to feel the tender through the larger breast muscle, its increase has been an indirect result from breast yield selection. In recent years the use of ultrasound has made it possible to measure this muscle directly.

Unlike the economically valuable white meat, the yield of dark meat has not changed much since 1957. Drum yield of the 1957 strain was 7.5 per cent of full-feed liveweight compared to 8.1 per cent and 8.2 per cent in the 1977 and modern strains, respectively.

Has Meat Quality Changed?

As the consumer market has changed and moved away from whole carcasses towards further processed poultry products and cut up carcasses, a relatively new area of research into poultry meat quality has emerged. Just as carcass conformation in the 1950s was important for visual appeal of the consumer, colour of cut up poultry pieces plays a role in consumer acceptability today.

But meat quality extends beyond colour. Meat quality is assessed by measurements of pH, temperature, colour, water loss and tenderness. The ability of poultry meat to hold water (water holding capacity) is critical to the success of many further processed products such as deli loaves. Poor poultry meat quality is usually associated with a condition called PSE (pale, soft, exudative) meat. PSE meat is characterized by a light, watery appearance and a mushy texture that when cooked can be tough. PSE can generally be described as condition where meat has high temperatures and a low pH after slaughter, which is associated with light colour, poor ability to hold water and tougher meat. Some studies have shown that meat from modern strains has characteristics of PSE meat.6

One of the most significant consequences of genetic selection has been an increase in yield, and with that it has been suggested that the unintended consequence has been decreased meat quality. Although we found that the pH and temperature of the modern strain was higher than the 1957 and 1977 strains 15 minutes after slaughter, there were no differences 24 hours later when rigor mortis was considered complete. As a result, there were no differences in lightness between the strains; however tissue from the modern strains appeared redder than the historic strains, which may affect consumer acceptability.

Drip loss measures the ability of meat to hold water. PSE meat is costly for the processing industry due to its poor water holding capacity. Cooked products, such as deli loaves comprised of PSE meat, may be of poor quality and crumble when sliced.

Repackaging products due to abundant water loss impacts the efficiency and bottom line of processors. Drip loss was lower in the 1977 (1.25 per cent) and modern strain (0.69 per cent) compared to the 1957 strain (1.78 per cent).

Water holding capacity also has an effect on tenderness, and thus consumer acceptance. Although drip loss was different between the strains, overall tenderness was not affected. The findings from this and other studies indicate that meat quality in terms of functionality has not deteriorated with genetic selection, but that some qualities of the meat, such as colour have been altered.7,8

What a difference 50 years make…

The modern broiler grows faster and more efficiently with more high quality meat yield at a younger age than its counterparts of 1957 and 1977. Breeding programs have evolved over the years to improve the balance between reproductive, economic and support traits. Though much of this progress can be attributed to genetic selection, it is important to remember that traits that are easily selected for (highly heritable) have heritabilities of 40 per cent.

This means that 60 per cent of the variation in a trait is due to environmental influences, such as management and nutrition. Such influence is evident in the large variability that exists in commercial performance from broilers with similar backgrounds.

How will things change in the next 50 years? There will certainly be new targets and challenges to overcome. Consumer preferences will continue to be very influential in the development and tweaking of breeding programs. Future products will be influenced by convenience, taste and healthiness. Increased concerns from consumers with respect to animal welfare and food safety will also play a key role, and have a significant impact on management practices.

Management must be dynamic to adapt to the new requirements of future generations of broilers. Producers who strive to optimize environmental conditions will benefit by allowing the genetic potential of broilers to be fully expressed.

References

1. Chicken Farmers of Canada, 2005.

2. Hess, C. W., 1962. Random-bred populations of the Southern Regional Poultry Breeding Project. World’s Poult. Sci. J. 18:147-152.

3.Chambers, J. R., D. E. Bernon, and J. S. Gavora, 1984. Synthesis and parameters of new populations of meat-type chickens. Theor. Appl. Genet. 69:23-30.

4. Havenstein, G. B., P. R. Ferket, S. E. Scheideler, and B. T. Larson, 1994. Growth, livability and feed conversion of 1957 vs 1991 broilers when fed “typical” 1957 and 1991 broiler diets. Poult. Sci. 73:1785-1794.

5. Emmerson, D. A., 2003. Breeding objectives and selection strategies for broiler production. In: Muir, W. M. and S.E. Aggrey (eds.) Poultry Genetics, Breeding and Biotechnology, pp. 120.

6. Berri, C., N. Wacrenier, N. Millet, and E. Le Bihan-Duval, 2001. Effect of selection for improved body composition on muscle and meat characteristis of broilers from experimental and commercial lines. Poult. Sci. 80:833-838.

7. Le Bihan-Duval, E., N. Millet and h. Remignon. 1999. Broiler meat quality: Effect of selection for increased carcass quality and estimates of genetic parameters. Poult. Sci. 78:822-826

8. Le Bihan-Duval, E. C. Berri, E. Baeza, N. Millet and C. Beaumont. 2001. Estimation of the genetic parameters of meat characteristics and of their genetic correlations with growth and body composition in an experimental broiler line. Poult. Sci. 80:839-843

Print this page