Roundup: New fans and ventilation systems

By Treena Hein

Features New Technology Poultry Equipment VentilationThe latest offerings on the market boost both barn energy efficiency and bird comfort.

Direct drive fans like the ones pictured here are becoming much more popular because of their energy efficiency and low maintenance requirements. PHOTO: DACS; MUNTERS

Direct drive fans like the ones pictured here are becoming much more popular because of their energy efficiency and low maintenance requirements. PHOTO: DACS; MUNTERS Following up on Canadian Poultry’s 2020 report on fan and barn ventilation developments, here is a round up of some of the exciting new offerings on the market this year. Now, more than ever, the latest versions of both fans and inlets are focused on increasing both energy efficiency and functionality in the poultry barn.

Fans

As expected, this year there are more direct drive fans available for producers to select from. These fans are becoming much more popular because their electricity consumption and maintenance requirements are very low – and their prices have come down.

Chore-Time, for example, has introduced 57-inch direct drive models of its ENDURA fan. Like other fans with direct drive motors, there are no belts, pulleys or bearings and, therefore, no need for regular lubrication. “Fan speed is controlled automatically by a CHORE-TRONICS 3 Controller, in combination with a variable frequency drive,” says Mindy Brooks, global marketing director. The company selected fan materials to provide corrosion resistance and maximum durability across the barn temperature range.

These fans also gain added efficiency due to their HYFLO shutters, which Brooks explains do not suffer the typical 12 to 15 per cent efficiency loss and air speed typical of traditional louver-style shutters. “So, air speed is maintained to the end of the flock, when it is needed most,” she says.

HYFLO Shutters also improve fan performance by minimizing obstructions during operation. “A cable attachment helps maximize efficiency by allowing the HYFLO Doors to float left or right together,” Brooks says.

“Other features of the direct drive ENDURA fans include a black, high-density polyethylene cone for light control, a long glass fiber composite shroud and HYFLO doors for durability. The units are engineered to have a slight downward tilt, making them self-draining.”

DACS

The new 57-inch MagFan ONe from DACS has achieved best-in-test at the BESS Lab at the University of Illinois, a well-known and trusted facility where experts evaluate fan efficiencies each year. That superiority, explains DACS president Niels Dybdahl, stems from a body design that allows air to pass through the unit with minimal power consumption.

The MagFan ONe can run with either an on/off set-up or with a variable frequency drive (VFD). The BESS Lab analysis showed a performance of 40,900 CFM (cubic feet/minute), 28.7 CFM/watt at 0.00 WC (measurement of static pressure).

DACS also now offers the MagFan Mini, a 30-inch wall-mounted direct drive fan with a capacity of 11,050 CFM and 23.5 CFM/watt at 0 Pascal (static pressure). Like the MagFan ONe motor, the MagFan Mini’s 0.3 kW motor can run in both on/off mode (60 Hz operation) or VFD mode, Dybdahl explains.

“Speed controlling via VFD allows for a 70 per cent reduction in electricity consumption and also brings a more predictable airflow pattern due to the variable fan speed,” he says. “Also, the more predictable airflow pattern ensures sufficient speed for the incoming air to travel far enough to be properly warmed before moving down to bird level.”

There are no replacement parts needed and no maintenance requirements for the MagFan Mini.

Both the MagFan and the MagFan Mini can be equipped with the MagDoor shutter system. MagDoor is a fast-operating roller door that substitutes conventional shutter systems and ensures completely unrestricted airflow and unsurpassed efficiency. MagDoor, with its insulated PVC segments, seals off a full-size wall fan like MagFan, to prevent backdraft and cold air ingress. Mounted in front of a MagFan with an additional fan cover on the outside fan cone, the combination offers excellent thermal insulation and air tightness.

VAL-CO

VAL-CO’s new V-Fan models also have a direct drive VFD and their permanent magnet alternating current (PMAC) motor provides greater efficiency than induction VFD-driven motors. BESS tests results show that a 54-inch V-Fan delivers up to 35,000 CFM at top speeds and provides up to 62.7 CFM/watt at low speeds; a 36-inch Fibreglass V-Fan delivers over 14,000 CFM at full speed and up to 43.0 CFM/watt.

The two sizes are available in galvanized, Z-Material and fibreglass finishes. Sean Francey, director of customer support, says that, in addition to energy savings, this fan will “potentially eliminate the need for smaller-size fans for minimum ventilation.”

Exhaust and heat recovery

Exacon now offers the AF24MQIE2 exhaust fan with multi-fan motor, with BESS labs test results of 14.0 CFM/watt at 0.10-inch static pressure (with cone). Exacon also offers the 54-inch direct drive variable speed fan from Better Air.

Other new offerings from Exacon include the Avi-Air Heat Recovery system, which preheats incoming air to help reduce heating costs. “The intake fan can be inversed in warm weather to work as an exhaust fan, turning the Avi-Air into a two-stage ventilation unit to evacuate stale, moist air,” president Mark Relouw says.

New inlets

In addition, Exacon offers the new TPI Air Inlets’ model called Ventum. Its universal dimensions make it easy to replace existing inlets. The curved inner valve helps guide air downwards to the birds during maximum ventilation. The polyurethane material (R-value of 0.93) offers high insulation value in cold weather.

Hog Slat has also added a new series of insulated side wall inlets to its product line up. They feature insulated curved inlet doors that directs incoming air to the ceiling for effective mixing before dropping to floor level, explains Austin Baker, Hog Slat’s ventilation director. Their plastic construction resists corrosion, while the flexible door seals tightly to minimize heat loss and air infiltration. The inlet series comes in two sizes, 13 by 44 inch rated at 3,700 CFM and smaller eight by 44 inch rated at 1,700 CFM.

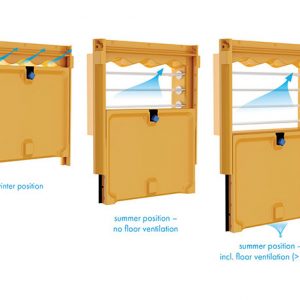

Munters has introduced the ZEW Flatwave compact wall inlet, which has air flow and air guidance decoupled, and four individually adjustable air conduction lamellas. In the winter position, the inlet allows a high throwing range of fresh air at minimal opening, but air is guided slightly upwards. During the summer, the flap allows an intake of warm fresh air along the wall downwards when open 75 per cent or more.

Munters has also released Weather Hood for Professional 2900 and Flatwave inlets. They provide improved resistance to high wind conditions and stress cracking, and have a white exterior with opaque black interior for improved light reduction.

Lastly, Munters’ new Horizon Tunnel Door is available in 36-inch or 42-inch heights and built to any length. They provide multi-row control using a single actuator and have a closed-cell foam interior, allowing the doors to achieve a R-Value of 8. These doors open to near 90° for maximum airflow and are designed for easy assembly with welded bracketry, minimum fasteners and minimum adjustments.

Print this page