Precision Feeding

By Martin Zuidhof University of Alberta and Kimberly Sheppard Livestock Research Innovation Corporation

Features Broilers Health EnergyNew innovative tool can improve flock uniformity

The goal of the Precision Broiler Breeder Feeding System is to control individual bird feed intake by precisely matching individual real-time body weight measurements to body weight targets

The hatching egg industry faces increasing production and welfare challenges due to ongoing genetic progress in broilers. The gap between growth potential and target body weight is increasing. Commercially, the genetic potential of individual birds is often not achieved because equal distribution of increasingly restricted amounts of feed is difficult. Feeding management (quantity of feed, frequency, and timing of feed delivery, feeder design, and feeder space) affects uniformity of distribution of feed, which ultimately affects uniformity of body weight. Poor body weight uniformity results in reduced reproductive success because of overweight and underweight birds.

For these reasons, Dr. Martin Zuidhof and his research team at the University of Alberta have been developing a Precision Broiler Breeder Feeding System toward providing an innovative integrated feeding management solution that will dramatically improve flock uniformity, increase chick production from each hen by close to 10 per cent, and improve bird welfare by providing feed more frequently than commercial management systems currently allow. The aim of the feeding system design is to control individual bird feed intake by precisely matching individual real-time body weight measurements to body weight targets.

The initial prototype was built and tested in 2013. With it, the researchers completed a 20-week pilot study with a small group of free run broiler breeder pullets, identifying design issues along the way and improving the design. A beta prototype has been manufactured, and a full 60-week broiler breeder precision feeding trial is underway. Although two pilot studies have now been conducted, this article focusses primarily on results from the scientifically replicated second pilot study on the first prototype.

In free run birds, the Precision Feeding Station controlled individual bird feed intake by accurately matching real-time body weight measurements of individual birds to body weight targets. All birds were able to individually enter the feeding station and eat in a protected enclosure. Birds were weighed in the station and offered feed if they were below the target body weight or gently removed from the station if they were heavier. Meal size and the amount of time they could spend eating were controlled by software settings. Output from the bird and feeder scales (2 readings per second) illustrate the form of the data the researchers were able to collect with the system. The meal size was less than the daily feed required to grow at the target rate so that birds received multiple meals each day. This allowed individual birds to “graze” throughout the day, which stabilized their metabolism. It is likely that more frequent feeding is beneficial for gut health. Wilson et al. (2013) found that feeding broiler breeders daily compared to skip-a-day improved gut health compared to every-other-day feeding.

Pilot research project #1

The first pilot study ran for 14 days, with a small flock of 25, 52-week-old Ross 708 broiler breeder hens. Birds weighing less than 3.5 kg were allowed to eat feed from the station for a 2.5 minute feeding bout before being gently ejected from the station. The researchers observed a significant decrease in the coefficient of variation in body weight of 0.17% per day. Birds in the low body weight group (those under 3.5 kg at the start of the trial) had a higher rate of gain than birds in the high body weight group (3.5 kg or higher at the start; 14.1 vs. -6.5 g/d). The results confirmed that short term precision feeding improved flock uniformity in older free-run broiler breeder hens.

Pilot research project #2

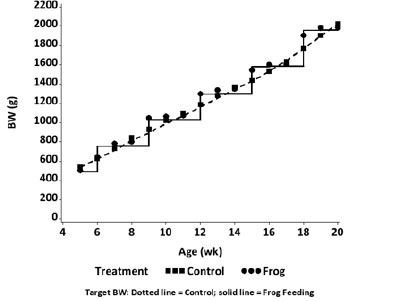

A second pilot project was started with 40 birds, but due to a design issue that has been corrected for the second generation prototype, the researchers were only able to feed 20 young birds reliably with the first prototype. At 4 weeks of age, 20 Ross 308 broiler breeder pullets were randomly assigned to two treatments (10 per treatment): Control, where the target body weight was updated hourly, and a Frog Feeding treatment, where the target body weight curve increased in ‘jumps’ once every 3 weeks. The frog feeding curve was designed to intersect the Control body weight curve approximately 1.5 weeks after the ‘jump’. On average, the body weight targets were the same in both treatments. The Frog feeding treatment was designed to simulate over- and under-feeding of broiler breeders that may occur in practice, particularly if flocks are not weighed often enough.

Since the body weight treatment was applied to individual birds, each bird was an experimental unit, even though they were housed in a single pen. If a bird was over its target body weight, it was ejected from the station. It received feed whenever its body weight was below the target. Meal size (amount of feed in the feeder) was adjusted and feeding bout duration (how long the birds were allowed to eat) several times over the course of the experiment to optimize functionality and to ensure birds could divide their feed over multiple meals per day.

Training day-old pullets

To train day-old pullets to eat feed from the station, a simple protocol with low labour input was developed. Feed was provided on chick paper on the litter outside the feeding station, and feed was also placed inside the station to entice birds to enter. In a matter of less than an hour, the first curious pullets had entered the station and started eating feed inside the station. The chick paper outside the station was removed, and after 3 days, the inside of the feeding station was the only place birds could eat feed, and all of the pullets ate ad libitum from the station for the first 3 weeks.

Results

Flock uniformity at 20 weeks of age was very high. The coefficient of variation in body weight was consistently below 5%. This compared to a coefficient of variation of over 9% in the extra 20 birds that were fed once per day in a conventional manner. Birds fed with the Precision Broiler Breeder Feeding System had a flock uniformity of 100% (birds within 10% of the mean body weight) in both treatments for 7 of the last 10 weeks of the pilot study.

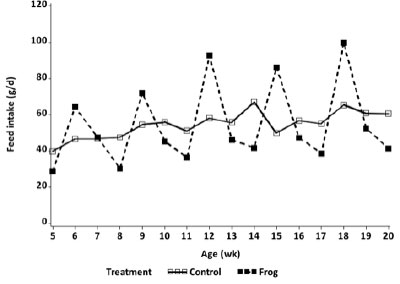

The Precision Broiler Breeder Feeding System can be used by all broiler breeders (pullets, hens, cockerels, and roosters). The researchers have successfully achieved two different body weight profiles, confirming that the Precision Broiler Breeder Feeding System was able to feed individuals according to separate body weight targets (Figure 1) by allowing differential access to feed. Figure 2 illustrates the variation in feed intake that resulted in achieving the different treatment body weight curves.

Informational video

The prototype Precision Broiler Breeder Feeding System worked better than expected, and the researchers wanted to let people know what they have developed and discovered to date. They produced a YouTube video to disseminate the results of the pilot project to help potential users of the system and the general public understand its benefits. The video provides background to the problem of achieving high flock uniformity, tells the story of the Precision Broiler Breeder Feeding System development, and identifies key results to date. The anticipated benefits are also outlined. The video can be viewed on YouTube or on the Poultry Research Centre Website.

To read more, please visit www.poultryindustrycouncil.ca.

Next steps

Three graduate students are currently working on the project. Teryn Gilmet, an MSc student, will build on her behavioural observations during the second pilot study. Her main objective is to determine how the PBBFS impacts welfare and bird behaviour, particularly in relation to behavioural vices such as aggression.

Paulo Carneiro and Sheila Hadinia, both PhD students, are evaluating the efficiency and metabolism of broiler breeder hens and roosters fed from the PBBFS compared to conventional skip-a-day feeding regimens. They will relate individual feed intake patterns to efficiency and body conformation. Flock uniformity and productivity in both systems will be the focus of their work.

Once preliminary studies are underway, we intend to apply for funding to run a full-scale commercial trial. Because of the information we can collect on individual birds, and the ability to control feed intake at a bird level, we can actually run a broiler breeder experiment with an ‘n’ equivalent to the size of a commercial flock (e.g. 5,000 hens and 500 roosters)!

Acknowledgement

Thanks to the entire project team shared a common vision for the PBBFS, and continually challenged each other to improve the design and functionality of the feeding station.

- Dr. Martin Zuidhof (Principal Investigator)

- Dr. Irene Wenger (Project Manager)

- Chris Ouellette (Agricultural Engineer)

- Airell DesLauriers (MSc student – modelling energy efficiency)

- Dr. Clover Bench (Ethologist)

- Teryn Gilmet (MSc student – animal behaviour)

- Josh Perryman (summer student)

- Mark Fedorak (Electrical Engineer – Xanantec Technologies Inc.)

- Chris Kirchen (Mechanical Engineer – Karve Machine Inc.)

- Dr. Edmond Lou (Electrical Engineer – Xanantec Technologies Inc.)

- Dr. Koos Van Middelkoop (Consultant – Koosidee, the Netherlands)

Financial support for the project was provided by Poultry Industry Council, Alberta Livestock and Meat Agency, Agriculture and Food Council, Alberta Innovates Bio Solutions, Danisco, Alberta Hatching Egg Producers, Canadian Hatching Egg Producers, Alberta Chicken Producers, and Maple Leaf Poultry.

|

|

Figure 1. Body weights (BW) of birds on Control and Frog Feeding treatments, illustrating the ability of PBBFS to manipulate BW automatically using real time measurements of BW to decide whether or not to allow birds to eat feed.

|

|

| Figure 2. Actual Feed intake of birds on Control and Frog Feeding treatments, illustrating the ability of PBBFS to use real time body weight (BW) measurements to allow birds to eat feed, or not. BW targets were updated hourly in the Control treatment, and once every 3 weeks in the Frog Feeding treatment. |

Print this page