Thinking Ahead

By Lilian schaer

Features Equipment Layers Poultry Equipment Production Poultry Production ProductionOntario producer installs North America’s first enriched pullet housing system

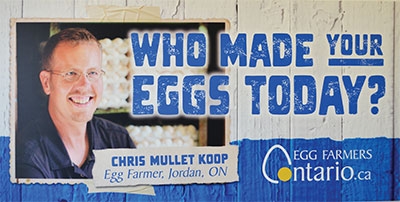

Chris Mullet Koop is involved with Egg Farmers of Ontario (EFO) in helping to promote the industry as one of several producers featured in the award-winning “Who made your eggs today?” campaign.

Chris Mullet Koop is involved with Egg Farmers of Ontario (EFO) in helping to promote the industry as one of several producers featured in the award-winning “Who made your eggs today?” campaign. Chris Mullet Koop didn’t set out to start growing his own pullets. He really just wanted to convert his layer barn into an enriched colony system – but as these things sometimes go, one thing led to another and then another. Now, he’s the first producer in North America with an innovative enriched pullet housing system called the Combi Pullet.

Mullet Koop farms with his wife Laura (who hails from a cattle ranch in Alberta’s Peace River region), and their three children near Jordan, Ont., the fifth generation on a farm started by his great-grandfather in 1932.

Today, in addition to capacity for 20,000 pullets per year, there are 5,500 laying hens, and 45 of their 57 acres are planted in wine and juice grapes. It was changing his laying hen facility into an enriched colony system that ultimately led him to growing chicks and to the Combi Pullet, which just won an innovation award at France’s largest poultry trade show.

“I’ve never grown pullets before. My whole project oriented towards converting the existing housing into an alternative system but we couldn’t do it in the existing barn so we built a new barn. So what do I do with the existing barn?” he explains. “It was Dad who suggested we could grow our own chicks and since most chicks grown in Ontario are grown in traditional cage housing or on the floor, I wanted a system that would complement my new layer facility.”

A lengthy search finally brought him to the Combi Pullet, developed by Farmer Automatic in Germany, which has interior LED tube lighting, interior feed troughs and three levels of perch space. It mirrors his layer system in almost every way except it doesn’t have nest boxes. But finding out everything he needed to know, and convincing himself that this was the one, was not easy.

“This is such a recent innovation that there are only one or two systems in France and Germany that have been installed. So I tried to get some data and information and talk to people who had seen it,” he says, adding that he finally managed to see a partition of the system at a display at the International Poultry Show in Atlanta this past January.

“I was sold on it, how the chicks would navigate and what the benefits would be.”

The system’s cages can be kept open or closed, which he says will give him the option to grow pullets for both conventional and different alternative housing barns in the future.

PUTTING IT INTO PRACTICE

His first pullet flock was 14 days old at the time of this interview in mid-September and he was very pleased with how things were working out so far, recording only a half per cent mortality rate during that time. The system came with a series of maps and charts to help guide him through usage and maintenance, and since he is the first farmer in North America to have the installation, the equipment supplier and others are closely watching his experiences in the industry, including the grader who buys their eggs.

“Everything has been charted, including what needs to be done environment-wise to keep the temperature, feed and water at appropriate amounts to get a good survival rate from hatching. But you’re still dealing with living animals,” he says, adding that although it’s going well so far, it’s his first time growing pullets so he’s not in a position to make comparisons with other pullet rearing systems.

“When they were eight days old, I noticed the first chick on a 12-inch perch and now, at 14 days, I’m seeing all of them on the two-foot-high perch,”

he says.

This is in contrast to what he has observed in his new layer barn with a flock that came from traditional pullet housing.

Very few birds use the second- or third-level perch, preferring to remain on the floor or use the front perch that is only three inches off the floor. He says it’s interesting to observe the difference in his pullet barn and he’s keen to see how his first flock of pullets will adapt to their layer cages when the time comes.

It was the increased focus on animal welfare-friendly production that helped the producer consider the switch to alternative housing. Before building his new layer facility, he’d been producing eggs in a conventional system, and although alternative housing options aren’t yet standard, he feels that’s only a matter

of time.

“The industry is moving increasingly towards alternative housing systems and looking more carefully at animal behaviour to try to create a production environment that will accommodate that,” he believes.

“It’s not a standard yet, but I can see this coming and our cages were almost 30 years old, so this was the time to

do it.”

He hasn’t noticed any production increase from his hens in the two and a half months they’ve been in the new layer barn so far, but he is hoping that will change in the long run. He anticipates being able to raise a better pullet with stronger bone structure that will result in fewer cracks or better longevity in the shell quality. It’s something he says he’ll be watching for over the next few flocks that he’s growing himself.

“Ultimately, my goal is to achieve the best results in cage-free rearing. I do want to open the cages and see how their bone strength and health develop and how that might alter when they lay as mature layers,” he explains.

Mullet Koop is also involved with Egg Farmers of Ontario (EFO) in helping to promote the industry. He serves as a zone councilor for EFO, has been an active member of the EFO speak-up team and was one of several producers featured in the highly popular and award-winning “Who made your eggs today?” campaign.

So when it came time to unveil his new facilities, he and his family hosted two open houses: one for the layer barn on June 21 and one for the pullet barn on Aug. 9.

The events attracted over 100 attendees, including farmers, processors, food service representatives, poultry specialists and even the World Society for the Protection of Animals.

It was the culmination of a busy year for the family, and now that everything is up and running, Mullet Koop is looking forward to a bit of quiet.

“It’s probably a small project, comparatively speaking, but it was a big one for our family. It was an intense year for us and I have a vineyard too that keeps me busy from April to August and that’s when all the construction took place this year,” he says.

“Right now, it’s quieter and I just appreciate being able to be here with my chickens and my family and no one else.”

Print this page