Value of commercial broiler trials

By Leasea Butler Technical Services Representative Cobb-Vantress Inc.

Features Broilers Production Poultry Production Poultry Research Research Cobb-Vantress Inc. Technical Services Representative Leasea Butler says you need to write your own story to make the best decisions for your complex, and that story is best told through a commercial trial.

Cobb-Vantress Inc. Technical Services Representative Leasea Butler says you need to write your own story to make the best decisions for your complex, and that story is best told through a commercial trial. In the poultry industry we discuss cost/profit/loss in terms of hundredths of pennies. Those same pennies in a year equate to millions of dollars.

Properly evaluating any input — such as breed choice, equipment or feed additives — at the broiler level can only be done with a properly designed commercial broiler trial within your complex.

Basing decisions on data collected from another complex or research is only a part of the story. In many cases it’s the beginning of the story, but can lead you down the wrong path for too long if not tested within your complex using your own system.

It might be tempting to follow the path of another complex, but more often than not there are nuances within your complex that will impact the end result. Most of the time you only have part of the other complex’s success story. You don’t have the same inputs or outputs.

A difference in live operations (inputs) and product mix (outputs) can greatly influence the profit/loss that might be generated by following the same path within your own complex. You need to write your own story to make the best decisions for your complex. That story is best told through a commercial trial.

The value attached to the decisions made based on the commercial trial results warrant a properly designed, communicated and executed trial.

A properly designed trial takes as many variables out of the equation as possible, except those you are comparing. For instance if you are testing different breeds, you want to have a farm with:

- Identical houses in equipment and design

- Two houses per treatment

- Same breeder flock ages

- Same hatchery and set date

- Same light, ventilation, feed and water programs

If there is a variable that could have influenced your data there will always be questions and concerns regarding the validity of the trial. The reason for at least two houses per treatment is that it allows you to choose one house from each treatment that closely mimics the other treatment in regards to mortality, morbidity and growing conditions. This takes out more of the variables that may have occurred during the growing cycle. Some of those variables that have been witnessed during the growing cycle are: running out of feed in one or more houses; environmental conditions; and chick quality

It is also recommended to repeat the trial or multiple trials for the same reason, but this is not always practical. Multiple trials help make the end picture clearer.

A properly communicated trial involves including many departments within your complex in a planning discussion weeks in advance. Having every department on board before the birds are set in the machines will result in the best outcome. Departments that need to be involved include: breeder department; hatchery; feed mill and delivery; broiler department; live haul; processing plant; and government institutions.

Communication about the trial will help minimize one of the biggest variables to a trial — human error. Assign a trial point person or persons to follow the trial through the process. All departments need to take ownership and understand the importance of the trial results.

A properly executed trial generates the quality data needed to make the right decision. Typically the data needed is from live as well as plant performance. To obtain accurate live data you should select a random sample of birds from one house for each treatment, as discussed previously, the day before processing.

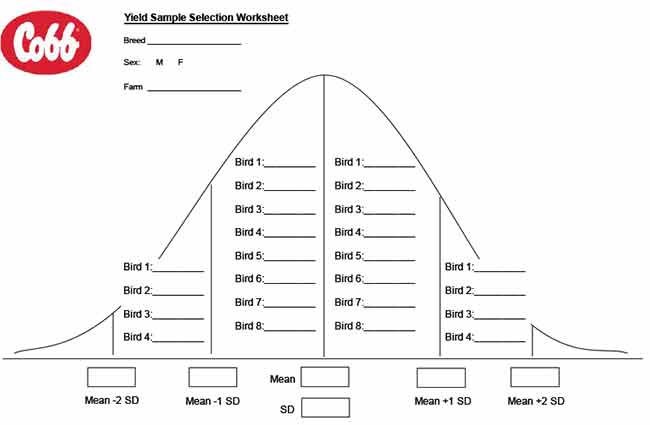

The weight samples should be kept separate by sex, and collected from three areas of the house: Back, Middle and Front. Either record individual weights, or use scales with the capability to calculate the standard deviation. Once you have your mean (average) and standard deviation for body weight (by sex), you can fill in the boxes that define the weight category cut-offs on either side of the mean (middle) weight (See image page 22). You will need to find the appropriate number of males and females for each weight range seen in the histogram below. In the end, you will have four males and four females that are between 1 and 2 standard deviations below the average weight, eight males and eight females that are between the average weight and 1 standard deviation below the average, etc..

These birds should be tagged and followed the following day to the plant. At the plant the birds should be reweighed and this individual plant weight will be your live weight. The birds should then be sent through your processing plant. This allows for you to see what the treatments will achieve in your operation. Typically, the carcasses would be removed from the line just before the chiller to take the variable of water uptake out of the equation.

The next step is to have a person that is well trained to debone the carcass and to collect the individual parts with the correct bird tag. Another person will need to record the weight for each individual deboned or whole part for each tag/band number. The data generated by your complex can then be analyzed.

Once you have the results from the well-executed trial, you can start working on the economics to help in your decision. The economic model should help you answer questions on how the inputs you are testing influenced your bottom line. These are some of the factors your economic model needs to consider:

- Will the change result in more/less housing needs?

- How did the change influence live performance? (FCR, mortality, growth rates

- How did the change influence processing performance? (Meat quality, yield, condemdation)

- Will the change result in updating your system? (Hatchery, feed mill, processing plant)

Take into account all the departments involved in the trial itself. Sometimes decisions may result in a positive for one department and a negative for another department. If you answer how each of those departments will be affected, your goal will have been met – the scenario that results in the most hundredths of pennies for your complex.

A link is provided below on how Cobb recommends performing a commercial yield trial:

http://www.cobb-vantress.com/academy/videos/video/cobb-commercial-yield-testing-2012

Print this page