Pullet rearing systems

By Frank Luttels

Features Barn ManagementAssessing the true cost of different options for raising young laying hens.

While aviary systems are more expensive than floor rearing systems, the key advantage is their compartmentalized design.

PHOTO CREDIT: Chore-Time

While aviary systems are more expensive than floor rearing systems, the key advantage is their compartmentalized design.

PHOTO CREDIT: Chore-Time Today’s producers have a few options when planning a pullet rearing system for commercial cage-free egg production. From floor rearing to aviary rearing, each type of system comes with a different price tag. What is challenging to see, however, is the true cost of each system after figuring in labour needs, bird mortality rates and other factors.

Consequently, it is critical for producers to look at all aspects of the operation to calculate long-term return on investment, instead of simply flocking to the solution that is cheapest to install.

Floor rearing systems

The least expensive housing option for pullet rearing is the floor rearing system. It is particularly attractive to producers who have old barns with some equipment already installed, making the cost even cheaper. Unfortunately, floor rearing systems are not ideal for training birds to succeed in a cage-free laying facility, as they lack many of the features found in laying facilities.

Although some floor rearing systems contain perches, the number of perches is usually inadequate for the birds to fully learn how to use them. Additionally, floor systems typically do not have slatted areas, so the birds never become comfortable walking on slatted floors. And if bell drinkers are used in the barn, the pullets likely will not accept nipple drinkers when transitioning to a laying system.

These issues highlight the importance of proper pullet training. Additionally, the hidden costs of floor rearing systems continue to add up throughout the lifespan of a flock, as poorly trained birds will not perform well in a laying house.

Instead of moving around the house exhibiting natural behaviours, birds will often resort to stressful behaviours, such as feather pecking or bunching up in the house, causing management problems. The typical result is a low percentage of grade-A eggs, high labour costs and a poor return on investment.

Floor rearing systems with platforms

Another pullet rearing option is a floor system with perches and adjustable platforms. In this system, a nipple line is located above the platform, requiring birds to jump, which is a huge improvement over standard floor rearing systems when it comes to pullet training.

These types of systems offer a mid-ranged cost of installation. Although the extra investment results in better bird training, producers who have them also pay high labour costs. Vaccinations, for example, can be difficult to perform when dealing with the very large flocks in these rearing systems. Not only is it difficult for many producers to fill the job openings to perform the required labour, but the added costs also erode return on investment potential.

Another big disadvantage of floor systems with platforms is higher bird mortality rates. For example, producers may bring in 105,000 pullets, fully expecting to lose 5,000 of them to achieve a laying flock of 100,000 birds.

A leading cause of the bird mortality with these systems is poor environment, and one of the main reasons for this is that the vast majority are installed without manure belts. Not only do manure belts reduce the amount of labour needed to remove the litter, but they also greatly improve the environment, leading to healthier and better performing birds.

Aviary rearing systems

A third option for pullet rearing is the aviary rearing system. In these systems, pullets can be closed in for the first few weeks, providing them a safe, comfortable and well-ventilated environment in which they have ample space to move and jump around. These systems include a lot of perches as well as adjustable platforms with nipple drinkers above them for bird training.

While such systems are more expensive than floor rearing systems, the key advantage is the compartmentalized design of aviaries, making access to birds much easier and significantly lowering labour requirements. Aisles alongside the compartments make catching birds for vaccination and other tasks much easier. Producers may even keep multiple flocks separated in one house, which is not possible with other systems.

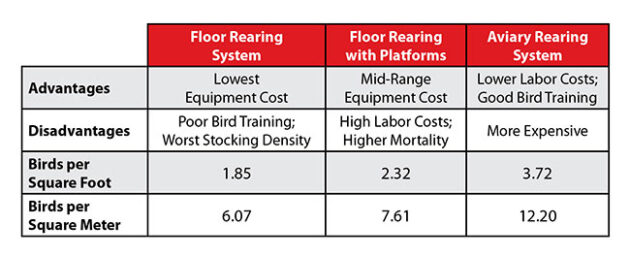

This table breaks down the long-term return on investment of different rearing systems.

Bird density

One of the best apples-to-apples comparisons of the three systems is bird density. With a floor rearing system, producers can stock about 1.85 birds per square foot (6.07 birds per square meter) of barn. Floor rearing systems with platforms can be stocked with about 2.32 birds per square foot (7.61 birds per square metre).

Aviaries can hold up to 3.72 birds per square foot (12.20 birds per square metre) of barn. Producers can double the number of birds in the same facility with an aviary rearing system versus a standard floor system.

Considering the huge expense of the barn space alone, it is logical to use that barn to house as many pullets as possible to help maximize the return. Further efficiency is gained through the fact that some equipment costs, such as ventilation, are the same for both aviary rearing systems and floor systems, spreading that cost out over more birds with an aviary rearing system.

Despite the higher stocking densities of aviary rearing systems, they can turn out birds with a very high uniformity percentage. The uniformity of birds reared in aviary systems translates into healthier birds and more grade-A eggs when they are moved into laying facilities.

Long-term ROI

In the end, what matters most is the long-term return on investment of each system. When considering the reduced labour needs, reduced mortality and higher quality birds produced in an aviary rearing system, producers can achieve greater profits with aviaries over a long-term period.

Those who wish to save money up front on floor systems – with or without platforms – may regret the decision after seeing returns diminished by lower bird densities, higher labour costs and, overall, poorly performing birds.

When building poultry housing for commercial cage-free egg production, virtually no producer enters into it planning for the business to last only a short time. In fact, many hope their operations will succeed for generations.

Unfortunately, it is difficult for producers to look beyond the initial installation costs of aviary rearing systems. However, these systems must be considered from a long-term investment perspective. Investing in the right system may just be the key to the long-term success of the farm.

Print this page