Solution for a Stinky Problem

By Tony Kryzanowski

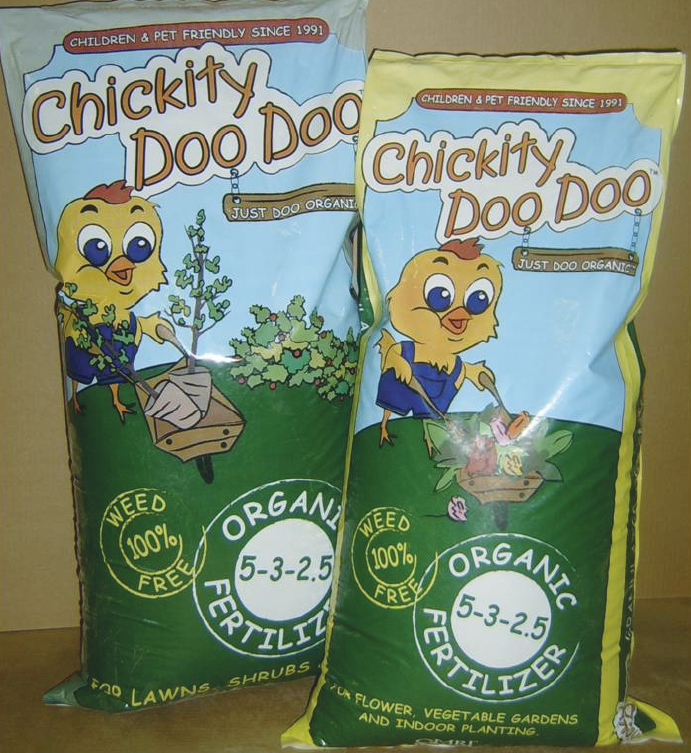

Features Business & Policy TradeWisconsin company cashing in on ‘Chickity Doo Doo’ interested in Canadian partnerships

Chickens do a poor job of processing nutrients, and this has created

huge headaches over the years for many egg-laying and poultry

operations when land-applying raw poultry manure, because of its high

phosphorus and nitrogen content.

|

|

| ‘Chickity Doo Doo’ is a composted product that has removed about 21,000 tons of raw poultry manure from being land-applied. R&J Partnership has produced about 13,000 tons of marketable, composted product for the agriculture, retail and golf course maintenance markets.

|

Chickens do a poor job of processing nutrients, and this has created huge headaches over the years for many egg-laying and poultry operations when land-applying raw poultry manure, because of its high phosphorus and nitrogen content.

However, a couple of enterprising businessmen in Lake Mills, Wis., have recognized this as a potential value-added benefit over other sources of raw manure when it comes to producing a superior organic fertilizer, and they are definitely interested in talking to Canadian egg-laying operations about potential partnerships.

“It’s a lot closer for us to cross the border into Canada with our technology than going to California or Florida,” says company co-owner, John Weiss.

When former teachers Weiss and John Nortman discovered a proprietary, patented composting system that would guarantee them at least a five per cent nitrogen content in the finished product, all the pieces fell into place for a poultry-based organic fertilizer that could be marketed as better than other run-of-the-mill composting products they intended to compete against. The result was the creation of a product called Chickity Doo Doo, the removal of about 21,000 tons of raw poultry manure from being land-applied, and the production of about 13,000 tons of marketable, composted product for the agriculture, retail and golf course maintenance markets.

“Coming out of the barn, we are at approximately six per cent nitrogen on chicken layer manure as opposed to a cow, which is probably closer to 1.5 per cent nitrogen, or a hog, which is maybe a little bit above that at two to 2.5 per cent,” says Weiss. “It also comes out at a much lower moisture content as opposed to cow manure or hog manure, which makes it easier for us to compost.”

He says they are dealing with roughly 55 to 60 per cent moisture content, as compared to 80 to 90 per cent moisture for raw cow manure and even higher for hogs on a consistent basis, which makes their poultry manure easier to compost.

Furthermore, because the chickens need to create a quality eggshell, they are fed a very high diet of calcium, which means that the producers of Chickity Doo Doo can also guarantee at least a nine per cent calcium content in their fertilizer. Research shows that calcium is another important contributor to plant health, says Weiss.

However, with higher nutrient content comes a tradeoff and that is an odour issue, more so on the retail side of the business than the agricultural side.

“We do, as part of our composting process, take some of the odour out,” says Weiss, “but that is part of the challenge for us. There are products that we are testing now that will be added to reduce odour and that allow us to keep our organic certification, but yes, if you retain a lot of the nitrogen and you retain a lot of the nutrients, the trade-off is odour. That is part of our next challenge.”

In 2007, R&J Partnership purchased the composting system that was operating simply as a manure management method at a massive egg-laying operation located between Madison and Milwaukee, Wis., called Creekwood Farms. The system was invented by one of the egg-laying farm’s owners. Creekwood Farms managed about one million chickens in its laying operation, and was producing a granulated and pelleted organic fertilizer product that it sold to fertilizer distributors, as well as organic and non-organic farms. Weiss describes their effort as “dabbling a little bit on the retail side,” but he and Nortman saw much more potential in it.

“He [Creekwood’s owner] was able to compost and create the high temperature for the pathogen kill and also retain the high level of nutrients,” says Weiss. “When we came across this patented system, we just thought it had too much potential to pass up.”

Since launching the Chickity Doo Doo product line in 2007, sales have doubled every year. The company hopes to achieve about $4 million in annual sales by next year. Distribution has also expanded from retail markets in the Midwest to large lawn and garden distributors on the east and west coasts. The product is registered for use in all 50 U.S. states. Sales to the retail and golf course sector have risen from eight per cent to 30 per cent of sales over that same period. Business is also growing in the agriculture sector, with conventional farmers seeing the value of blending the poultry-based organic fertilizer with their synthetic fertilizers.

“Our product is 30 per cent carbon,” says Weiss, “so conventional farmers want to return carbon and the microbial cultures to the soil to improve the soil along with using synthetics. So, they are blending it or in some cases, going to our product solo even though they are a conventional farm.”

This has resulted in huge demand for the poultry-based organic fertilizer to the point where R&J Partnership has run out of product at times and is in discussions with numerous other egg-laying operations that are interested in getting out of land spreading.

“What we have offered is the ability to come in and solve a problem for them,” says Weiss, “where we take the pressure off them from the standpoint of having to land-apply and having to work with state or federal agencies on nutrient management plans.”

In terms of Canadian partnerships, he says the company wouldn’t necessarily be opposed to a technology licensing arrangement, but would prefer to install and operate the equipment on site themselves, in consultation with egg-laying companies, to ensure that the composting process does not interfere with normal egg-laying operations. A number of compensation options are available, such as receiving a percentage of sales, or payment strictly on a per ton of raw manure basis. However, Weiss adds that many of their clients are willing to simply give them the manure because of the savings they achieve by not having to land-apply it, and given that Chickity Doo Doo is willing to take on all the liability.

R&J Partnership underwent a massive expansion in April 2008 when it purchased the Creekwood Farms egg-laying operation in partnership with Daybreak Foods Inc., which now provides 20,000 tons annually of Chickity Doo Doo’s raw manure supply. At the time of purchasing the composting system from Creekwood Farms, R&J Partnership wisely acquired right-of-first-refusal on the purchase of the entire egg-laying business to ensure that they’d still have a consistent raw manure supply to support the organic fertilizer business if the egg-laying operation was ever put up for sale.

“According to Wisconsin Department of Natural Resource officials, we are the first, large, concentrated animal feeding operation in the history of the state of Wisconsin that has no land application of raw manure associated with our operation,” says Weiss.

Because Creekwood Farms is a caged egg-laying operation, the manure falls onto belts that convey it to a collection site in the barn. R&J Partnership has four Knight manure spreaders to transport the manure from the egg-laying barn to the composting barns. The manure is indoors at all times, avoiding any runoff issues.

The manure is processed using the proprietary system to achieve optimal moisture content, and is normally composted over a two-week period. There are three points in the process where the temperature reaches in excess of 150 F, which works as an inoculation and helps to assuage concerns over such issues as bird flu. The compost is then processed through a Knight auger mixer, which breaks it up before it is pelletized at one of the company’s two California Pellet Mill (CPM) units.

The pellets are marketed as the company’s commercial organic fertilizer for agriculture operations, but a portion is processed through a cracker crumbler that crumbles the product so that it can be applied easily with a standard lawn fertilizer spreader. This product consistency is bagged and marketed as Chickity Doo Doo, but the process also produces a fine dust. This is collected and marketed as a greens-grade organic fertilizer for golf courses.

Weiss emphasizes that what they are using is 100 per cent poultry manure from egg layers, as opposed to poultry litter used in poultry-for-meat operations that is often mixed with sawdust or bedding, two materials that tend to dilute the nutrients in an organic fertilizer product. They also scrape out the manure on a daily basis as opposed to poultry-for-meat operations that typically clean out their barns every eight to nine weeks between flocks, meaning that R&J Partnership is able to keep odour to a minimum.

R&J Partnership is participating in a pilot project funded by a non-profit company called Farm Pilot Project Coordination Inc. The company essentially searches out and helps to develop technologies aimed at creating value-added projects from raw manure rather than land-applying it. The project with R&J Partnership involves an in-vessel system to convert poultry mortalities into compost to see if a high nitrogen content can be achieved in the final product by using this composting method. The project is also measuring the discharge of ammonia, volatile organic compounds (VOCs), methane, carbon dioxide and oxygen, and investigating the possible use of scrubbers particularly to mitigate the discharge of VOCs.

If proven after the one-year project, it may offer a one million bird operation an opportunity to dispose of 300 to 400 carcasses at one time on a weekly basis, says Weiss, and produce a marketable compost product in the process.

Print this page