Stocking Density

By Martin J. Zuidhof Associate Professor University of Alberta

Features New Technology ProductionFinding a balance and effects on the broiler value chain

You’ve come a long way, baby. A century ago, chickens were grown in

arguably dreadful conditions, with limited shelter from the elements

and poor nutrition

You’ve come a long way, baby. A century ago, chickens were grown in arguably dreadful conditions, with limited shelter from the elements and poor nutrition. Relatively speaking, society’s attitude toward animals was much more doministic. Much has changed. It’s remarkable to reflect on the fact that women have been allowed to vote for less than 100 years! Over the past 50 years in particular, the broiler industry has been a hotstove of innovations that have drastically reduced the cost and greatly increased the quantity of chicken produced for food. Recent data from the Poultry Research Center shows that broiler chickens grow almost five times as fast as broilers 50 years ago!

|

| The TradeOff: Broiler density has been researched extensively, with varying results regarding bird welfare and quality of product. Ultimately, density is a tradeoff between the welfare of the broilers and the welfare of the producers. Advertisement

|

However, this progress has not been problem free. Unintended consequences of unbalanced selection programs emerged in the form of serious metabolic and skeletal disorders. Justifiably, concerned consumers raised issues about animal welfare. Many of these concerns have been and continue to be addressed through high tech breeding and management programs, but the perception that rapid advances in growth rate and efficiency have occurred at the expense of the bird are firmly entrenched in the minds of consumers. Through global competition, consumers demand cheap poultry meat, yet they have a negative perception about stocking density and pen sizes.1 The poultry industry faces a dilemma. Should the industry yield to societal pressure to produce cheap food, and the temptation to maximize profits at the expense of the animals that they rely on? On one hand the consumer expects cheap food, and makes food choices largely on the basis of price. On the other hand, they are concerned (to varied degrees) about animal welfare. Being generations removed from agriculture, many consumers are frankly shocked at the sight of intensive broiler production.

There is no debate about the fact that high-density broiler production done well is more profitable for producers and reduces costs for consumers.

However, high density broiler production leads to tangible quality issues such as scratching, cellulitis, and foot lesions, and intangible quality issues such as consumer perception of animal welfare and the general wholesomeness of their food. Just as there must be genetic limits to progress, there must also be ethical limits to how many birds should occupy the limited space inside modern production facilities. Finding the right balance between cheap food, profitable production, product quality, and ethical production practices is a difficult and sensitive problem.

Most production research focuses on decreasing variable costs of production. It’s been pointed out that less has been done to address fixed costs or the ‘dirti-five’ (depreciation, interest, repairs, taxes and insurance).2 Stocking facilities at higher density directly is a natural strategy to tackle fixed broiler production costs.

Current Canadian code of practice (CARC-CRAC 2006) provides the following recommendations:

- Chickens raised in floor pens should have enough freedom of movement to be able to stand normally, turn around, and stretch their wings without difficulty.

- Broilers and roasters should be provided adequate space to feed and drink without restriction.

- The recommended weight per unit of floor space is 31 kg/m2.

- However, variations in stocking density up to 38 kg/m2 are acceptable if justified by adequate husbandry programs, feeding and watering equipment, ventilation systems, lighting programs and litter materials. Extra space is recommended in hot summer weather.

Published results of stocking density research have been reported, and the conclusions are that stocking densities above 38 kg/m2 reduced final BW, feed intake and food conversion, increased the incidence of foot-pad dermatitis, scratches, bruising, poorer feathering, and condemnations.3 In Europe, the Broiler Welfare Directive was drafted in 2007, and will be implemented in the UK this year (2010). The directive allows stocking densities of up to 42 kg/m2, if welfare monitoring over seven previous cycles meet Directive standards, particularly with regard to mortality.4

This article provides background information on effects of stocking density on broiler performance and well-being, and offers insights from work performed at the Poultry Research Centre.

Implications of High Stocking Density

Broiler Performance

There has been extensive study of the effect of stocking density on broiler performance. In general, high stocking density results in decreased feed consumption, reduced body weights and little change in feed conversion.5-16 Most of the reduction in body weight occurs toward the end of the production cycle when the density as a function of kg/m2 is the greatest.17 Because the reduction in body weight is the result of decreased feed intake, higher nutrient density diets increase the effect on body weight reduction.18

|

Broiler performance results are somewhat variable, and may depend on environmental conditions, which may vary with season, antibiotic use, or other interactions, known or unknown.8,19 For example, several researchers have not observed a reduction in feed intake, or have observed a negative effect on feed conversion efficiency as a result of increased stocking density.7,11,14,16,20-22 Farmer (1985) found that unthriftiness in broiler flocks is associated with high stocking density and poor basic husbandry.24 The condition is largely preventable by good management.

In general, stocking density does not affect mortality.8,11,15 However, there are some reports of increased mortality with higher stocking densities.20,22

Broiler Well-being

There has been a tremendous amount of work on the implications of stocking density for the well-being or health of broilers. Increased stocking density is related to increased fearfulness 24-26. Decreased skeletal integrity is also negatively affected by increased stocking density. The incidence of tibial dyschondroplasia increases, and “gait score” or walking ability decreases.26-28 Birds raised at .05 m2/bird had higher incidence of breast blisters and ammonia burns compared to birds reared at .07, .09, or .22m2/bird.10

Plasma corticosterone level, which is an indicator of long-term stress, increased significantly from a stocking density of .0116 m2/bird to .0697 m2/bird.29 Another study concluded that a stocking density of 43 kg/m2 compromised bird welfare whereas it was not clearly demonstrated that a density of 27 kg/m2 improved welfare in comparison to that in birds stocked at 35 kg/m2.30

Broiler Health

A 1960 study reported that high stocking density (White Leghorn cockerels) resulted in adrenal hypertrophy, suggesting that birds at high stocking densities may be immunocompromised.31 This is likely the cause of reduced immune responses observed at high stocking densities. Birds housed at lower stocking densities (10 or 14 birds/m2) had a greater antibody response to Newcastle Disease than birds housed at 18 birds/m2, and response was further reduced at 22 birds/m2.32 Similarly, four-week-old chicks were found to have a reduced immune response and body weight when housed at higher stocking densities (10, 15 or 20 birds/m2).33 High stocking densities have also been found to result in decreased bursa and thymus weights.19

In a survey of the poultry industry in the UK, it was found that stocking density increased the incidence of ascites.34 Two epidemiological studies in Northern Ireland in which 2000 flocks (28.6 million birds) were surveyed over four years identified that stocking density increased the incidence of contact dermatitis.35 No significant association between stocking density and cellulites was found in a study conducted the following year.36

An immune response requires energy expenditure by the bird. If birds at lower stocking densities were challenged by a pathogen, they would likely be better equipped to mount an immune response. This would have an energetic cost only if the birds received the immune challenge. A slow immune response, which may be expected at higher stocking densities, would likely result in greater mortality or morbidity, thus reducing efficiency.

Barn Environment

The environment of the birds is often negatively affected by increased stocking density. Wet litter and increased ammonia production (van Middelkoop 1997) are associated with increased stocking density.5,14,37 However optimal management, which would include adequate ventilation rates, decreases these problems. Litter management or adequate ventilation may be the reason that some investigators found no change in litter quality as a function of stocking density.13,22 Counterintuitively, a survey of 50 commercial broiler farms in Alberta demonstrated that higher stocking density was linked with improved quality scores, and lower heat stress. However, these results were greatly influenced by management of the bird environment, such as ventilation rates and misting systems.

A study has shown that E. coli populations in the litter decreased with increasing stocking density (5 vs. 15 birds/m2).39 It’s been demonstrated that litter quality deteriorates with increased stocking density, however, no relationship was observed between litter quality and contamination of carcasses in this study.5

There is some evidence that reducing stocking density will not immediately improve the bird environment. A German research team observed no difference in litter quality when birds were housed at 33-36 kg/m2 or 25-32 kg/m2.13 A separate study concluded that a reduction of bird density to 30 kg/m2 (unspecified, but probably from approximately 40 kg/m2 ) will not have an immediate and strong effect on improving air quality and heat stress in summer.40

It’s been proposed by researcher K. Elwinger that maximum permitted stocking densities in broiler houses should be related to the quality of the management of individual farms.41 On the basis of his work, the maximum stocking density permitted for broilers in Sweden has been increased since 1994 from 25 to 33 kg live weight per m2 floor area for farmers fulfilling certain levels of management.

In a landmark paper in Nature, a University of Oxford group of researchers concluded that legislation of stocking density that does not consider other aspects of the bird environment would have major cost implications for producers, and would likely not have the desired improvements in animal welfare.42

Bird Quality

Many studies have demonstrated that carcass quality deteriorates with increased stocking densities.10 Elfadil et al. observed that carcass scratch scores were significantly correlated with stocking density.43 Although they found find a significant association between abdominal scratches and cellulitis, they found no significant association between stocking density and cellulitis.

It’s been observed that feathering begins to deteriorate at a density of 30 kg/m2.7 This may be part of the reason for increases in the number of scratches observed in birds housed at higher stocking densities. Stocking density, strain of birds, and degree of feathering could all be considered as potential risk factors for abdominal scratches in broiler chickens.43 A significant increase in the incidence of breast blisters in females, with a similar trend approaching significance for males has been demonstrated in birds reared at 0.037, 0.056, 0.074 and 0.093 m2 of floor area/bird.6

Increases in stocking density have resulted in increases in dermatitis, skin lesions and scabby hips, increases in sores, scabs, scratches and bruising, and decreased numbers of grade A carcasses.44-47

Although it’s been found that stocking density had no effect on carcass contamination and the relationship between litter quality and contamination of carcasses has been inconclusive, if the litter were to have a significant level of pathogen contamination, it is likely that there would be an increase in carcass contamination at the time of processing. Birds transported in contaminated transport coops were found to have a higher incidence of contamination.48

Economics

Many investigators have concluded that the maximum economic potential for the production unit, based on their research, was in their highest stocking density treatment. Here are some of the findings:

- optimum profit per m2 could be obtained when birds are raised at .05 m2/bird.10 production of live weight/m2, and profit margin, increased as stocking density increased up to 17 males and 19 females/m2.15 The performance of broilers at 10, 20, 30, 40 or 50/m2 was investigated. He concluded that profit margin/m2 increased almost linearly, by about ,0.65 for every bird/m2 increase in stocking density. He further concluded that there is a clear tradeoff between the well-being of the producer and the broiler. 17

- Reducing the floor area by 0.2 ft2 per bird from the benchmark densities for broilers would result in at least a $.01/kg increase in returns of live meat produced and large savings in construction costs.2

- Returns over feed and chick are reduced on a per bird basis, but increase linearly on a per unit floor area basis 2,6

- Under Dutch conditions, 20-22 broilers/m2 was found to yield the highest profit/m2.14

- When broilers were raised at 22, 14, 11, 9 and 7 birds/m2, it was determined that the most profitable stocking density was 11 birds per m2. This conclusion was based on body weight gains, however, and did not take into consideration fixed costs of production.16

High stocking density may have an early growth benefit (first two weeks), but results in decreased BW late in production.17 Higher stocking densities early in the production cycle (weeks one to three) are possible and even recommended, optimizing the existing capital, and effectively reducing fixed costs per kilogram in a production unit.29 Where markets exist for lighter birds, the practice of placing birds at very high density and removing some at an earlier age and lighter weight makes good economic sense. From an economic standpoint it is possible to reduce fixed costs by brooding birds at higher densities and expanding their usable space as they grow by moving chicks from barn to barn or by some other means.

The choice to increase stocking density in broiler production is usually made in order to maximize economic returns from a production unit. However, this objective is not always met. There is an optimum stocking density to maximize economic returns, but the optimum stocking density varies based on environmental conditions and management of the birds. It is imperative that birds raised at high stocking densities receive adequate feeder and water space. Adequate ventilation rates are absolutely essential for good performance. In the summer, additional thought about removing heat from the vicinity of the birds is required, possibly with the use of tunnel ventilation or recirculation fans.

Implications for Nutrient Intake

Activity

Birds tend to be less active at higher stocking densities.25 Increasing housing density has been shown to reduce the distance traveled by broilers, but did not affect the number of visits to the feeders and water cups.49 Because there is an energy requirement for activity, one would expect that broilers housed at higher stocking densities would have a reduced energy requirement.

Feed Intake and Growth

Several studies have shown that broilers tend to eat less at high stocking densities, resulting in slower growth rate, and reduced final body weights. Birds housed at higher densities may spend less time eating, thus reducing nutrient requirements slightly. Because of reduced growth rate, the maintenance requirement is increased. The nutrient requirement for growth is also less because birds raised at high stocking densities do not achieve the same body weight as those at lower densities.

Low Level Stress

High density production acts as a non-specific stressor.31 The bodies of these birds are in a high metabolic state, which allows for quick response to stimuli. This more active metabolic state means that the nutrient requirement for birds raised at high densities is greater.

Thermal Regulation

Early in the cycle, high density production can be beneficial. The optimum temperature for chicks is around 30°C. Having birds in close proximity to one another allows for improved conservation of that heat or transfer from one chick to another. In hot weather, high-density production often results in inefficient nutrient utilization because feed intake is reduced, and birds may be heat stressed.

Immune Function

High density production often results in an increase in sores, scabs, and scratches. Birds with these conditions must often mount an immune response, which represents a nutrient cost. The wave of insult may include particles of dust in the lung, or skin scratches. The incidence of both is higher with increased stocking density.

Economic Analysis of an Alberta Stocking Density Trial

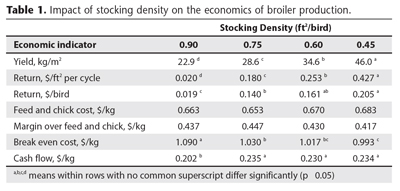

A stocking density trial using 14000 broilers was conducted at the University of Alberta Edmonton Research Station.50 Four stocking densities: 0.90, 0.75, 0.60, and 0.45 ft2/bird were used (.084, .070, .056, and .042 m2/bird). Chickcop©, an Alberta Broiler Chicken Economic Model, was used to evaluate the economics of rearing broilers at different stocking densities.51 This analysis has been done from the perspective of an investor trying to determine an appropriate building size.

Each of 32 pens x 2 trials was treated as an experimental unit, or separate economic entity (n=64). The growth rate, body weight, FCR, mortality, and condemnations specific to each pen for each trial were entered into the Chickcop economic model (version 2.00). The model calculates the cost of broiler production, breaking down the costs of production to specific fixed and variable input costs. The following economic outputs of the model were analyzed:

- yield (kg/m2)

- return ($/ft2 per cycle)

- return ($/bird)

- feed and chick cost ($/kg)

- margin over feed and chick ($/kg)

- break even costs ($/kg)

- cash flow ($/kg)

Limitations

It is important that the interpretation of the economic analysis be done in the context of the limitations and assumptions, which are outlined below.

- The performance of birds in the research pens may not exactly mimic performance of broilers in a commercial setting.

- The birds used in this experiment represent a single strain (Ross 308).

- The birds used in this experiment were all of one sex (female).

- The study was performed during the summer in warm to hot weather.

- High ventilation rates were used which ensured bird comfort.

- High performance feed rations were provided.

- Bird quality at processing generally decreased with higher stocking densities. This is not taken into consideration in the economic model

Assumptions

- The economic analysis is based on identical output from a 50,000 quota unit broiler farm in Alberta at 87.5 per cent utilization (129,500 kg live). In order to achieve production at this level, placements numbers of chicks were adjusted to compensate for mortality. This is typical of an investor trying to determine the appropriate building size for 50000 quota units worth of production.

- Capital costs are based on new buildings @ $11.00/ft2, and equipment costs set at $4.00, $4.15, $4.35, and $4.50/ft2 for birds housed at 0.90, 0.75, 0.60, and 0.45 ft2/bird, respectively. These capital costs were arrived at in consultation with a commercial builder and a commercial equipment supplier.

- Feed costs are based on current feed prices for high performance rations (April, 1999).

- Money invested into capital costs was assumed fixed at $1M. Any monies above this were treated as borrowed money, to be paid back at a rate of $9,500/month.

- An interest rate of 7.25 per cent per annum was used on borrowed money.

- Labour inputs were assumed to increase by 7.5 per cent with each increase of 0.15 ft2 per bird in stocking density. Labour inputs at 0.90 ft2/bird were set at 7.25 hours per 1000 birds, and were calculated as 6.49, 5.59, and 4.50 h per 1000 birds for birds housed at 0.75, 0.60, and 0.45 ft2/bird, respectively (based on 515, 554, 596, and 640 h total labour per 8 wk cycle, respectively). A fixed barn size was assumed for this estimate.

- Utility costs were assumed to be 20 per cent higher in the highest stocking density compared to the lowest stocking density, due to increased ventilation and heating requirements. A sliding scale was used to calculate utility costs of $1550, 1653, 1756, and 1860 per month for birds housed at 0.90, 0.75, 0.60, and 0.45 ft2/bird, respectively.

- Repair costs were assumed to be fixed, as any increased density factor would likely be offset by the smaller barn space.

- A producer price of $1.10 (Alberta Chicken Producers live price, April, 1999) was used to calculate returns and margins.

Results

|

Yield. Stocking density had a dramatic effect on yield (kg/m2). Yield was 22.9, 28.6, 34.6, and 46.0 kg/m2 in the 0.90, 0.75, 0.60, and 0.45 ft2/bird treatments, respectively.

Feed and chick. The cost of feed and chick was not significantly different between treatments. The mean feed and chick cost was $.6670/kg. Margins over feed and chick averaged $0.433/kg, and did not significantly differ between treatments.

Returns. All other economic parameters showed significant differences between treatments. Returns per square foot were highest in the highest stocking density treatment ($0.427/ft2), and decreased with decreasing stocking density, to a low of $0.020/ft2 (Table 1 on page 24). Returns per bird were significantly higher in 0.75 ft2/bird than the 0.90 ft2/bird treatment. The next significant increase in return per bird was realized at the 0.45 ft2/bird density.

The bottom line. Cash flow was not significantly different between the 0.60, 0.75, or 0.45 treatments. Cash flow was, however, reduced in the 0.90 treatment (see table 2). The reason cash flow did not differ among the three higher stocking density treatments is because the loan payment and other fixed costs were held constant, and depreciation, which varies as a function of the different capital requirements, is not a cash expense. This underscores the point that cash flow is not necessarily the best indicator of long-term sustainability of an enterprise.

Recommendation. Break even cost is the best indicator of the true cost of production. According to this analysis, maximum economic returns are achieved at a stocking density of 0.60 to 0.45 ft2/bird. Cost of production increases markedly when stocking density decreases from 0.75 to 0.90 ft2/bird. Therefore production at or above 0.90 ft2/bird is not recommended.

Production factors affecting quality

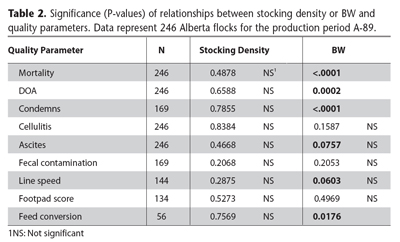

In the summer of 2009, the Alberta Chicken Producers (ACP) Quality Committee requested assistance to investigate the impact of production conditions on broiler quality. A preliminary regression analysis was conducted to study the impact of production input variables such as body weight (BW) and stocking density on the incidence of mortality, condemnations, cellulitis, foot-pad scores, and fecal contamination. Regression analysis is a statistical model that measures the mathematical relationship and degree of relationship between input variables and output variables.

Methodology

The study was based on actual data submitted by three Alberta processors for a single period (A-89; Jan/Feb, 2009). Input variables included BW and stocking density, and the output (quality) variables included mortality, transportation mortality (DOA), condemns, cellulitis, ascites, fecal contamination, line speed, footpad score, and feed conversion. The relationship between the input variables on the output variables was determined using the REG procedure of SAS (SAS Institute, 2009).

Results

Significance of relationships between key variables is presented in Table 2. No significant relationships were observed between stocking density and quality parameters. Mortality (r=0.31), DOAs (r=0.23), and condemnations (r=0.31) tended to increase in higher BW broilers (P<0.05). Ascites (r=0.11) and line speed (r=0.16) showed weak statistical relationships to BW (P<0.10).

What the Data Showed

In the current pilot analysis, significant relationships between stocking density and quality parameters were non-existent. Larger birds tended to have higher rates of mortality, DOA, and condemnations. There were some problems with the data, however. For example, mortality rates for many of the lower weight birds were negative, indicating a problem with the reporting of mortality rates.

In the Nature article “Chicken Welfare is Influenced More by Housing Conditions than by Stocking Density” the study was extremely large by industry standards -utilizing 2.7 million birds – and the researchers found that bird environment was more important than stocking density for mortality.42 They reported temperature and humidity during rearing as having the most important impact on mortality. Although they found that gait scores were negatively affected by increased stocking density, they concluded that legislation of stocking density that does not consider other aspects of the bird environment would have major cost implications for producers, and would likely not have the desired improvements in animal welfare.

Conclusion

The current pilot study showed little relationship between production conditions and quality parameters. A larger study, spanning a longer time period, and involving more rigorous data integrity would be needed to evaluate these relationships with appropriate levels of confidence.

Cost of production is an important performance indicator. However, it should not be the only important consideration in broiler production. The entire value chain must be considered. Research and anecdotal reports from industry indicate that barn environment and resulting carcass quality deteriorates with increasing stocking density, reducing the value of the birds to the processor. Production stocking densities should be decided on after careful consideration of the facility (ventilation capacity, feeder and waterer space), as well as processing and marketing objectives.

For a full list of references, please visit www.canadianpoultrymag.com. Click on “current issue” to find this article.

Print this page