Winter broiler barn ventilation

By Martijin Gruyters

Features Barn ManagementMaintaining target temperatures for broilers without forfeiting optimal air quality.

It is impossible to properly ventilate a house that doesn’t seal well. Check how well sealed the house is by using a very simple pressure evaluation test.

It is impossible to properly ventilate a house that doesn’t seal well. Check how well sealed the house is by using a very simple pressure evaluation test.

Progress in genetics, nutrition and management has led to remarkable improvements in the daily growth and feed efficiency of modern broilers. The benefit of these advances is a dramatic reduction in the time a modern broiler takes to achieve market weight. Thus, for every hour in which the birds lack optimal temperature and ventilation, valuable performance will be lost.

The greatest challenge facing any producer is the dynamic comfort zone requirements during the broiler life cycle, which also depend on the region of the world and season. However, during the winter, when outside temperatures drop significantly, tremendous challenges arise between maintaining target temperatures without forfeiting optimal air quality.

House sealing

It is nearly impossible to properly ventilate or control temperatures in a poultry house if it is not well sealed. Any cracks, leaking fan shutters, poorly sealed inlets or poorly installed roof insulation will reduce the ability to control static pressure.

Poor static pressure control means a large percentage of fresh air will enter the house through leaks. In this case, higher fan capacity is required to achieve the correct air volume and velocity across the inlets and will cause over-ventilation and increased heating costs. In addition, it will be difficult to maintain target temperatures, particularly at night, and leaks are sources of cold drafts, which may cause health issues for birds and wet litter.

Most modern sidewall fans have shutters mounted on the inside, which can be sealed with a sheet of plastic placed between the shutter and the frame during the winter. The larger cone and box-type fans used for summer ventilation can also be sealed with a plastic cover on the outside. The negative pressure created in the house will pull the plastic against the fan shutters to help the seal. Large doors are also easily sealed by placing a large plastic sheet on the outside.

The following is a very simple pressure evaluation test. The fans used for the test are based on house floor area:

Close all inlets and doors.

Run the equivalent of 18 m3/h of fan capacity per m2 of floor area (e.g., 2,000 m2 × 18 m3/h =36,000 m3/h of fan capacity). Depending on the fans installed, it is not always possible to get a perfect match.

Measure the static pressure across any small opening, such as a slightly opened inlet or hole.

A static pressure of >37.5 Pa indicates the house is adequately sealed. Static pressure < 25 Pa indicates a poorly sealed house, which will require maintenance. A newly commissioned house should easily achieve a static pressure of 60 Pa. Always record the results of your pressure tests for future reference.

Minimum ventilation

Minimum ventilation systems are designed to manage air quality levels and moisture using fans on a cycle timer. This system is independent of the temperature control system and needs to be designed and operated in such a way that it will maintain good air quality and moisture control for optimal broiler development.

With minimum ventilation, there are three main factors to consider.

Firstly, continuous genetic improvements result in higher metabolic and growth rates, which in turn increase oxygen demand. These increased metabolic rates also mean increased metabolic heat production, moisture deposited in the litter via the feces and levels of carbon dioxide production – all of which must be removed by the minimum ventilation system.

Firstly, continuous genetic improvements result in higher metabolic and growth rates, which in turn increase oxygen demand. These increased metabolic rates also mean increased metabolic heat production, moisture deposited in the litter via the feces and levels of carbon dioxide production – all of which must be removed by the minimum ventilation system.

Secondly, due to the increased heater run times during the winter, more stress will be put on the minimum ventilation system, as there is more waste gas produced from the heating system.

Lastly, during the winter, there is a tendency for producers to reduce minimum ventilation rates as a means of maintaining temperature and reducing energy costs. However, this can cause poor air quality.

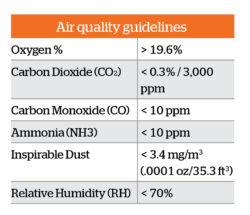

Air quality parameters for poultry can be defined as: During the winter, it is particularly challenging to meet air quality parameters due to the dilemma of maintaining temperature and optimal air quality. When heating capacity is limited, there is a tendency to reduce the minimum ventilation to prevent heat loss. At the same time, carbon dioxide levels and relative humidity (RH) will increase, which will have a negative impact on the development of the bird and the litter conditions. The correct programming of the minimum ventilation is the only effective method to control these parameters.

The importance of controlling carbon dioxide levels

Oxygen is an important component in physiological processes, and birds will require a minimum level for optimal performance. In a poultry house, carbon dioxide is continuously added to the environment by the birds and heating system, particularly in the winter, and brooded with constant heater usage. The carbon dioxide levels should be kept below the maximum range of 3,000 ppm as increasing levels of carbon dioxide will displace oxygen in the house. When carbon dioxide levels exceed the maximum level of 3,000 ppm or 0.3 per cent, oxygen availability will be low, resulting in inactive birds, reduced feed and water intake and a higher risk for the development of ascites.

The importance of controlling RH levels

Like carbon dioxide, moisture will be added to a poultry house mainly by the birds and gas heating systems. Birds will add moisture through respiration, drinking and excreta. The combustion of one m3 of gas adds one litre of water vapour into the air. If this added moisture is not removed from the house, the RH will increase and cause wet litter problems.

The RH needs to be kept below 70 per cent whenever possible. The only means to remove excessive moisture is by increasing air temperature and air exchange rates. As air temperature increases, its moisture holding capacity will also increase, which significantly increases the amount of moisture that can be removed by the minimum ventilation system.

Inlets and heat circulation

Inlets are arguably the most important part of the house ventilation system. Positioning and design of the inlets will significantly impact the direction of the incoming cold air. In many regions of the world, outside winter air temperatures are low with potentially high levels of RH. This cold, moist air needs to be heated before reaching bird level. Due to stratification, air temperatures are always the hottest at the ceiling or roof peak. Incoming cold, moist air needs to be directed to the peak and mixed with the hot air before reaching bird level.

In cold weather, air inlets should only open from the top, directing the incoming air to the peak of the house. Poorly sealed and designed inlets that leak from the sides or base direct a significant amount of cold heavy air onto the floor. This cold air is a source of drafts and wet litter.

The opening of the inlets should always match the fan capacity and generally have a minimum opening of five centimeters to produce an optimal air jet. A smaller opening will not produce a strong enough air jet that can reach the center of the house. For optimal air distribution, the incoming air needs a smooth surface to flow along to ensure it reaches the center of the house where it can mix with the hot air in the peak of the roof.

During the brooding stages, not all of the inlets are used so that the minimum opening of five centimetres is achieved. It is always best to ensure that opposite pairs of inlets are open or closed for an optimal airflow. Any inlet that is not in use should be completely closed because leaks cause pressure losses.

Inlet openings should be pressure controlled to maintain a constant airflow at different fan capacities. When cables are being used to operate the inlets, give special attention to the nylon cords closing the inlets. Cables can stretch and cause uneven openings. Inlets that do not close completely will cause pressure loss and energy loss.

There are many different designs and setups for circulation fans. Their main function is to break up the natural heat stratification in the house. It is not unusual to see up to a 10°C difference between the ceiling and floor level. These systems are designed to mix the air from floor to ceiling and remove significant levels of moisture from the litter.

Check this list to prepare for the winter

- Properly seal all fans that are not used during ventilation during the winter.

- Seal tunnel inlets when not used during the winter.

- Perform a leakage test to check for house sealing.

- Make sure all inlets completely close.

- Check all nylon connectors and cords. Any connectors that are broken or bad quality should be replaced.

- Make sure the front door seals well or provide additional sealing after receiving the birds (with wood shavings or plastic coverage).

- Check operating system settings (P-band, summer offsets, etc.) and make sure these are set for the winter period (cold air correction, RH correction, etc.).

Martijin Gruyters has 21 years of poultry industry experience, 14 of which have been at Cobb. In his current role as senior manager of technical services, he services the European region. Martin holds bachelor’s and master’s degrees in animal science from the Wageningen University & Research.

Print this page