Getting pests to fly the coop

By Alice Sinia Ph.D. Resident Entomologist — Regulatory/Lab Services Orkin Canada

Features Profiles Researchers Poultry Production ProductionSome helpful tips to reduce risks associated with pests

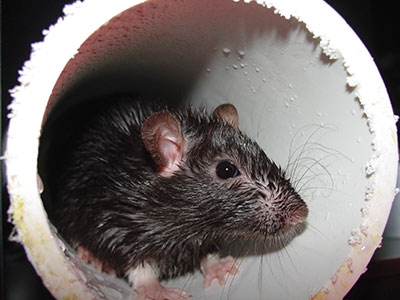

Rodents do not like to be out in the open. An important step to deter them is to eliminate places or objects where they like to congregate

Rodents do not like to be out in the open. An important step to deter them is to eliminate places or objects where they like to congregate According to the Public Health Agency of Canada, roughly one in eight Canadians suffer from food poisoning each year. That’s an estimated four million people who are subject to a preventable illness that, in severe cases, can be fatal. From farm to table, there are a number of opportunities where pathogens, allergens and irritants can be introduced to food, but prevention starts at the first step of the supply chain — the farm.

Pests, such as flies, rodents and cockroaches, are the primary sources of contamination. Recognizing and preventing pests that contribute to foodborne illness will help shield you from its costly and damaging effects, including: loss of revenue: reduction in product recalls; a damaged reputation; and potential disciplinary action from regulatory agencies. So, what can you do to protect your product and reputation?

It starts with an Integrated Pest Management (IPM) program for all steps along the process, and this includes your feed mill, layer facility, egg processing facility and storage. IPM is the most effective and environmentally friendly approach to preventing pest issues and employs sanitation and facility maintenance processes to eliminate the potential for pest issues. The goal of this approach is to restrict pests’ access to the three elements they need to survive — food, water and shelter. An IPM program is recommended for all industries, but has its roots in the agricultural industry where it originated to limit the use of chemical treatments around food.

While there are a number of pests that can affect poultry, the real threat to food safety comes from flies, beetles, birds and rodents. Here are some helpful tips to reduce the risk of disease spreading to poultry.

Flies

Known to transmit more than 100 known pathogens, including E. coli, Salmonella, Staphylococcus and Shinglla. Making matters worse is the fact they leave behind pathogens every time they touch a surface. One of the best ways to manage these pests is by hanging insect light traps in strategic locations. These newly designed traps attract flies using ultraviolet light and capture them on a non-toxic adhesive trapping board inside the unit. The silent devices are discrete, so you can place them in virtually any location. The non-toxic glue-board means you don’t have to worry about airborne contamination from insect parts like you would with the traditional “bug zapper.” They also operate around the clock so you have a continuous barrier against flies.

Beetles

Beetles can spread dangerous pathogens, but they can also cause extensive structural damage as mature larvae bore into structures seeking safe pupating sites. The two most common beetles associated with the poultry industry are the lesser mealworm and hide beetle. They are often difficult to control as they migrate throughout structures and pupation occurs out of sight. Glue boards and pipe traps are the best tools to monitor for the presence of these beetles. By recognizing the presence of beetles in a timely manner, as well as identifying the species, your pest management provider can take the appropriate actions.

Rodents

Rodents are known to carry more than 40 viruses and bacteria, including Salmonella, Hantavirus and Trichinosis. Rodents spread disease through their droppings and urine. They can also cause significant structural damage to your facility. These pests are found in fields, but are also a major concern in and around storage facilities. Ultrasonic devices can help deter these pests though additional measures are often required.

For starters, eliminate congregation points for rodents. Rodents do not like to be out in the open, so regularly cut the grass surrounding your facility and limit debris, like piles of wood, trimmings and decayed product, from the property. Facility maintenance steps, like sealing cracks and crevices around coops to limit access. Although mechanical traps and non-toxic baits can be used to control rodents that find their way through these initial lines of defense, recent technological advances can help identify a rodent issue before it turns into an infestation. Electronic scanning uses barcodes on pest management equipment so you can scan traps, for instance, to determine the number of rodents caught in a given period of time. This technology is even more effective when paired with electronic reporting, another new technology which produces customized web-based reports that measure trend data over time. By identifying hot spots, appropriate corrective action can be taken.

Birds

More than just a nuisance, birds are known to carry more than 60 diseases, such as Histoplasmosis (a sometimes deadly acute respiratory disease), and they can transmit dangerous bacteria like Salmonella. Diseases can spread through their droppings, so it is important to keep them at bay. One of the most effective ways of managing these pests in fields is the use of sound devices or noise canons. By identifying the species of birds in your area, your pest management professional can manipulate sound frequencies to simulate a distress call which drives them away. Physical deterrents, like specially trained dogs, scare-eye balloons and cellophane streamers, can also scare birds away. Often, it is a combination of technologies that work in tandem to reduce bird presence.

The beauty of an IPM approach is that it focuses on “common sense” sanitation and facility maintenance steps to proactively reduce pest pressures. By partnering with your pest management professional you can strengthen the protocols and processes you already have in place to further reduce the potential for foodborne illnesses and limit the risks that come with contaminated product.

An effective IPM program implemented throughout the supply chain will help ensure food is safely delivered to the end-consumer, but it requires a commitment from everyone involved in the process to make sure shipments are pest-free. By working to combat pests during the first step of the supply chain, you can help protect the end-consumer, as well as your business, from the headaches (and stomach aches) that pests can bring.

Alice Sinia, Ph.D. is Resident Entomologist – Regulatory/Lab Services for Orkin Canada focusing on government regulations pertaining to the pest control industry. With more than 10 years of experience, she manages the Quality Assurance Laboratory for Orkin Canada and performs analytical entomology as well as provides technical support in pest/insect identification to branch offices and clients. For more information, email Alice Sinia at asinia@orkincanada.com or visit www.orkincanada.com

Print this page