Flavex Technologies Introduces First Food Technology that Reduces Purge for Increased Yields

By Canadian Poultry

Features New Technology ProductionA new technology that simultaneously reduces juice purge in meat, poultry

and seafood by 3-to-4 percent, depresses microbial load and inhibits

the growth of Listeria monocytogenes has been introduced by Flavex

Technologies.

Two University Challenge Studies Confirm Findings of Flavex BioProtection Coatings™ on Meat, Poultry and Seafood

A

new technology that simultaneously reduces juice purge in meat, poultry

and seafood by 3-to-4 percent, depresses microbial load and inhibits

the growth of Listeria monocytogenes has been introduced by Flavex

Technologies, a division of The Arnhem Group, of Cranford, N.J. The

patent-pending development is believed to be the first food technology

to combine these critical capabilities.

Two university challenge

studies, conducted at Ohio State University, identified the remarkable

capability of Flavex BioProtection Coatings™—which are based on

Flavex’s well known protein products—to block the growth of Listeria

monocytogenes and to reduce purge and prevent color deterioration in

meats, poultry and seafood.

Economic Impact

“More

than a billion dollars is wasted each year, because of unattractive

discoloration in meat that occurs before unacceptable microbial counts

are reached,” Michael Bonner, president of The Arnhem Group, explained.

“One of the studies showed that the beef industry alone would save $762

million dollars if retail loss due to product unacceptability could be

reduced by only 3.6 percent.

“Flavex BioProtection Coatings

can dramatically increase shelf-life for packaged meat, poultry and

seafood products,” Bonner added. “The technology is so simple that it

can be applied in a local supermarket as well as in a major food

processing plant.”

Flavex Technologies is a division of The

Arnhem Group, which has produced multi-functional ingredients for the

food industry since 1980. The Arnhem Group provides innovative

ingredients to enhance the flavor of processed foods and beverages and

to aid food producers in designing food systems to meet the diet

demands of consumers.

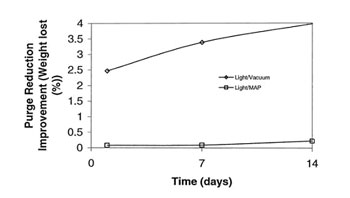

Flavex BioProtection Coatings use a gel

matrix to reduce moisture exudates by 3-to-4 percent of gross weight in

carcass meat, roast, ground beef, beef tenderloins, pork loin, salmon

filets and chicken breast in comparison to control samples, the

university study found. Purge reduction also resulted when the coating

was applied to pork bellies, fresh pork livers, sausages and smoked

poultry pieces.

The coating matrix extends shelf-life by

providing a barrier to water and oxygen, thereby reducing purge,

microbial loads, color deterioration and rancidity.

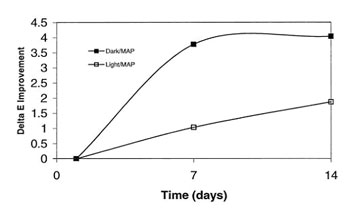

A

reduction in color deterioration was noted when the coating was applied

to fresh beef loins, ham and bacon pieces, fresh pork chops, sausages,

turkey steaks and cod fish filet patties.

In addition to

protecting the food from bacterial growth and reducing juice purge, the

gel matrix has the added benefit of protecting many core ingredients

from heat, moisture and acidity during food processing.

By

reducing purge BioProtection Coatings limit microbial growth and

increase product safety. The reduction in purge also maintains better

flavor, texture, color and weight in meat, poultry and fish.

Danger of Listeria

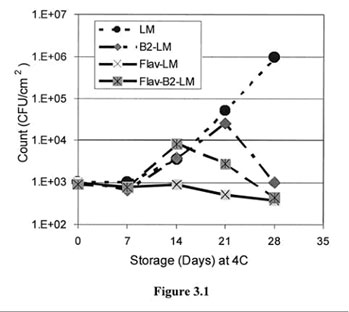

The

control of Listeria monocytogenes—one of the most dangerous food-borne

pathogens—is a major problem for the food industry. The Centers for

Disease Control and Prevention note that virtually everyone who

contracts listeriosis, the disease brought about by Listeria

monocytogenes, is hospitalized. Of the 2,500 people infected in the

United States each year, 500 die—a death rate of 20 percent.

Listeria

monocytogenes can grow in temperatures down to 3° Centigrade, making

refrigeration ineffective in controlling the bacterium. Vacuum

packaging and modified atmosphere packaging have proven similarly

ineffective in controlling Listeria monocytogenes.

A listeriosis

outbreak is devastating for the individuals who become ill and for the

food processor that made the food, if the illness can be traced to its

facility. Food recalls and plant shut-downs costing millions of dollars

can result.

The patent-pending technology encapsulates flavor

oils, oleoresins and spices in a colloid gel. The gel matrix may be

used in gel form and injected or mixed into meat products, and it may

be used directly in the food system or further processed before it is

added to the food system.

Encapsulation assists in maintaining a

separation between the food processing ingredient and air, thereby

reducing the opportunity for oxidation, degradation or other chemical

reactions.

The Flavex BioProtection Coatings protect the food

ingredients even if high processing temperatures are used to convert

the matrix into a liquid.

Coatings Enhance Anti-Microbial Agents

Flavex

BioProtection Coatings inhibit the growth of Listeria monocytogenes by

themselves, and enhance the effectiveness of anti-microbial agents,

which can be added before, during or following the application of the

coating.

There is virtually no impact on the perceived smell or

taste of protected foods. They provide clean labeling, as the coatings

need not be declared on the front ingredients panel. Diapers, which are

conventionally placed beneath packaged meat, poultry and fish, can be

eliminated. This will make the packages more appealing to consumers.

Additional

information about Flavex BioProtection Coatings may be obtained from:

Flavex Technologies, a division of The Arnhem Group, 25 Commerce Drive,

Cranford, NJ 07016-3605. Toll-Free Telephone: (800) 851-1052, fax:

908-709-9221. E-mail: info@arnhemgroup.com, Website: www.arnhemgroup.com.

The following graphs are taken from the challenge studies conducted at Ohio State University:

Print this page