Retrofitting older layer barns

By Frank Luttels

Features Barn ManagementSome egg producers looking to retrofit older barns with aviary systems have been challenged by low clearances in their existing houses. Fortunately, some of the latest advancements in aviary design have addressed this issue.

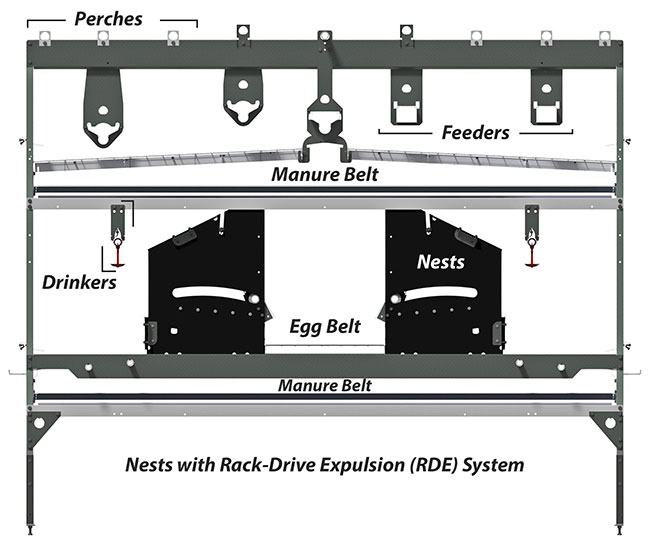

An illustration of an aviary system that can be adapted to an older poultry house with a lower ceiling.

PHOTO CREDIT: Chore-Time

An illustration of an aviary system that can be adapted to an older poultry house with a lower ceiling.

PHOTO CREDIT: Chore-Time For growers looking to transition from caged to cage-free egg production, most experts recommend using a multi-tier, or European style, aviary. That’s because this type of aviary offers the best combination of excellent bird welfare, optimum bird density, low labour requirements and a superior long-term return on investment.

While the high return on investment is attractive to growers, some have been challenged by low clearances in their existing houses. As a result, the adoption of multi-tier aviaries has been limited. Fortunately, some of the latest advancements in aviary design have addressed this issue.

Clearance challenges

When converting an existing poultry house to cage-free egg production, some growers have been unable to fit multi-tier aviaries under their pitched roofs, especially along sidewalls where the clearance is lowest. And, if the aviaries do fit, they may not provide enough space between the aviary and the roof to provide an adequate amount of ventilation needed to maintain a healthy environment.

Multi-tier modifications

As more North American growers transition from caged to cage-free eggs, engineers have taken note of the height challenge and begun developing solutions to modify multi-tier systems to better fit low-clearance houses. A new solution is to merge the bottom and middle levels, creating a two-tier aviary that’s less than 84 inches tall.

Despite the shorter size, the two-tier aviary maintains many of the same advantages of the original three-tier design. Additionally, it meets cage-free requirements worldwide.

There are two keys to the high performance of the two-tier model: perches are kept on the upper level; and water is still located in front of the nests.

The top level with perches and feeding systems provides an ideal sleeping environment. This helps provide good ventilation and eliminates hot spots in the house. In the morning, the birds will wake up, feed on the upper level and get thirsty. Then, they move to the lower level to find water. After drinking, the birds naturally find their way to the nests to lay eggs.

Instead of a lower level with feeding, these two-tier aviaries have a manure belt under the nest level with a wide platform in front of the nests.

Not only does this design provide ample space for natural bird activities, but it also keeps a clean environment with minimized ammonia levels, thanks to the manure belt.

To match the width and varying heights of a building, multiple aviary configurations can be used in one poultry house.

For instance, a two-tier system can be used along the walls, where clearance is lowest. Then, a three-tiered aviary can be used in the centre of the house, where the roof peak provides more room.

Properly trained birds enjoy moving across the aisles from one level to the next, resulting in excellent welfare and high performance.

Growers who implement this system find that birds use it instinctively well, minimizing hot spots and floor egg issues that are common with other aviary types.

Frank Luttels is layer product manager for Chore-Time.

Print this page